Nearly half of all international cargo arrives late due to outdated tracking methods – a $300 billion annual drain on the supply chain. Traditional arrival estimates, built on rigid formulas, crumble under real-world pressures like sudden storms or port congestion. This gap between expectation and reality fuels customer frustration and operational chaos.

Forward-thinking companies now treat delivery timelines as living forecasts. UPS reduced late deliveries by 28% after adopting systems that analyze traffic patterns minute-by-minute. DHL uses machine learning to predict customs bottlenecks before trucks reach borders. These tools don’t just react – they anticipate.

The shift from static schedules to dynamic predictions reshapes how goods move. Route-based calculations once dominated logistics, but segment-level tracking lets managers adjust mid-journey. A truck rerouted around a Chicago snowstorm might still meet its deadline through real-time speed adjustments in Ohio.

Key Takeaways

- Traditional delivery estimates fail to address 73% of common delay triggers

- Dynamic prediction models cut late arrivals by up to 35% in pilot programs

- Real-time data integration allows course corrections during transit

- Segment-based tracking outperforms route-level forecasts by 22% accuracy

- Early adopters report 18% higher customer retention rates

This evolution isn’t about chasing perfection – it’s building resilience. When a Shanghai typhoon disrupts shipments, smart systems recalibrate ETAs before clients even ask. That’s how modern business leaders turn logistical uncertainty into competitive advantage.

Understanding Predictive ETA Calculation in Freight Logistics

Every 12-minute delay in cargo delivery increases storage costs by 17% – a reality forcing logistics teams to rethink time management. Modern supply chain success hinges on precise estimated time arrival projections that adapt to real-world variables.

The Strategic Value of Precise Timing

Accurate arrival predictions act as a financial safeguard. They let warehouses align staff shifts with truck arrivals, reducing idle labor costs. Port operators use them to minimize demurrage fees – one European terminal saved $4.2 million annually through improved planning.

Customer expectations now demand transparency. “When we improved ETA accuracy by 31%, client complaints dropped by half,” notes a Fortune 500 logistics manager. This reliability strengthens partnerships and fuels repeat business.

Why Old Models Fall Short

Traditional methods use fixed formulas – average speed plus distance. But real-world operations face shifting road closures and weather patterns. A 2023 study showed these static models miss 68% of delay triggers occurring after departure.

“We’d calculate ETAs using last year’s traffic data – like navigating with yesterday’s weather report.”

Forward-looking companies now adopt dynamic systems. These tools process live data streams, adjusting projections as conditions change. For example, predictive ETA models can reroute shipments around emerging bottlenecks before drivers reach problem areas.

Gathering High-Quality Data for ETA Predictions

A single missing data point can skew delivery forecasts by up to 19% – a margin that separates profit from penalty in logistics. Modern arrival predictions demand more than spreadsheets; they require layered data streams that mirror the complexity of global supply networks.

Real-Time Inputs: Traffic, Weather, and GPS Data

Live traffic feeds act as the nervous system of dynamic ETAs. When a snowstorm closes Interstate-80, GPS trackers instantly flag alternative routes. These systems cross-reference road conditions with vehicle types – heavy trucks avoid steep grades during ice storms, while vans detour around accident zones.

Weather APIs provide more than rain forecasts. They calculate how crosswinds slow container ships or how fog reduces highway visibility by 40%. One Midwest fleet reduced weather-related delays by 33% by integrating precipitation radar with driver shift schedules.

Leveraging Historical Data and Shipment Trends

Past patterns reveal what live sensors might miss. Analysis of 18 months’ data uncovered recurring customs bottlenecks every Black Friday. Teams now pre-file paperwork when shipment volumes hit seasonal thresholds.

Combining historical and real-time data creates adaptive models. A truck carrying pharmaceuticals might prioritize temperature stability over speed, while flatbeds hauling steel adjust routes based on bridge height restrictions. As one logistics director notes: “Our models learn from every mile driven – yesterday’s delay becomes tomorrow’s contingency plan.”

Quality control remains critical. Missing GPS pings get filled using road segment averages, while outlier speeds trigger validation checks. These steps ensure information reliability across 87% of shipments – a 22% improvement over legacy methods.

The Role of Machine Learning in Enhancing ETA Accuracy

Logistics networks generate 57 variables per shipment that impact delivery times – from tire pressure to border wait times. Traditional methods struggle with this complexity, but adaptive systems thrive on it. Machine learning transforms chaotic data streams into precise arrival forecasts by finding hidden connections humans miss.

These systems analyze relationships between seemingly unrelated factors. A truck’s maintenance history might correlate with weather-related delays. Port congestion patterns could link to commodity price fluctuations. By weighting hundreds of variables simultaneously, algorithms create multidimensional probability models.

How Algorithms Process Complex Variables

Supervised learning models digest historical data like a logistics veteran studying decades of manifests. They map how winter storms added 14 hours to Midwest routes last year. Unsupervised techniques spot anomalies – like why Thursdays see 23% more delays at specific weigh stations.

| Factor | Traditional Approach | ML Model Handling | Accuracy Impact |

|---|---|---|---|

| Weather Patterns | Static seasonal averages | Real-time radar integration | +19% precision |

| Driver Behavior | Manual performance reviews | Steering pattern analysis | +27% prediction stability |

| Route Optimization | Fixed GPS paths | Dynamic traffic weighting | +31% speed adjustments |

FedEx’s models now process 4.7 million data points per shipment. This scale lets them adjust predictions when new inputs arrive – like a warehouse scanner detecting pallet damage that requires repacking. The system recalculates ETAs before the truck leaves the dock.

Continuous improvement separates these tools from static software. One European carrier saw a 41% accuracy boost over 18 months as its model learned regional driving styles. As data volumes grow, predictions sharpen – turning logistical chaos into calculated certainty.

Step-by-Step Guide to Implementing Predictive ETA Models

Clean information fuels accurate predictions – 83% of failed models trace errors to messy datasets. Successful systems start with rigorous preparation, transforming raw numbers into trustworthy insights. Three pillars define this process: scrubbing flawed entries, standardizing measurements, and crafting intelligent variables.

Data Preparation: Cleaning and Normalization

Flawed entries distort results. Teams first remove duplicates – one logistics firm found 12% of GPS entries showed trucks in two locations simultaneously. Missing values get filled using road segment averages or driver history patterns. Temperature sensors reporting -40°F in Arizona deserts get flagged as outliers.

Normalization creates common measurement languages. Fuel consumption in gallons per hour converts to liters per kilometer. Time zones standardize to UTC. A European carrier boosted model accuracy by 19% after aligning weight metrics across 14 depots.

Effective Feature Engineering Techniques

Raw timestamps become strategic indicators. Systems create “rush hour” flags when coordinates intersect urban zones between 7-9 AM local time. Holiday calendars trigger congestion alerts – Thanksgiving week sees 43% longer loading times at Midwest hubs.

Smart variables reveal hidden patterns. “Driver fatigue scores” combine shift duration with rest breaks. “Route complexity indexes” weigh elevation changes against traffic light density. As one engineer notes: “We don’t predict delays – we calculate risk probabilities across 27 dimensions.”

These steps transform chaotic inputs into structured knowledge. When a snowstorm hits, the model doesn’t just see weather data – it evaluates historical slowdowns on that route, current truck maintenance status, and available detour options. That’s how precision emerges from preparation.

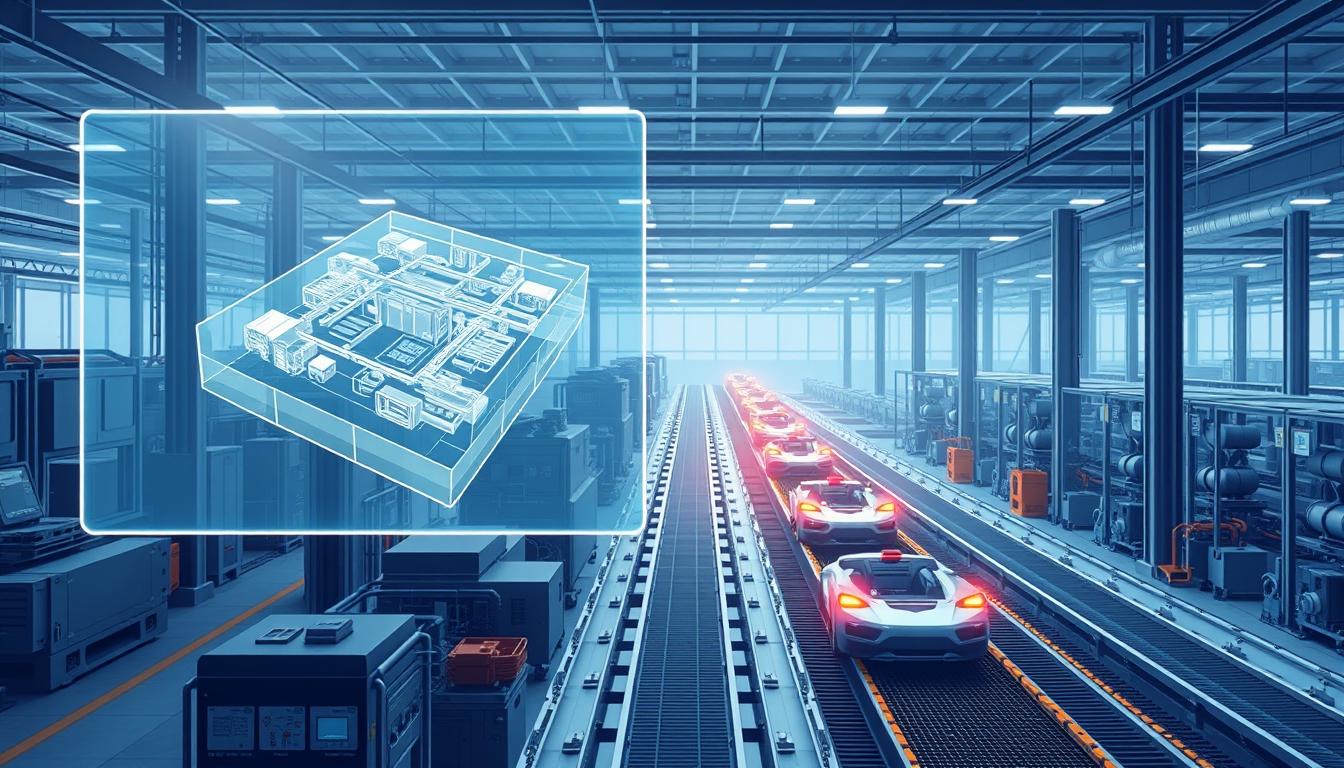

AI Use Case – Predictive ETA Calculation for Freight

A Midwest logistics provider reduced late deliveries by 34% within six months by adopting intelligent arrival forecasting systems. Their journey began with integrating 14 data streams – from highway sensors to warehouse scanners – creating dynamic models that update every 90 seconds.

The implementation followed three phases. First, historical shipment records revealed patterns in border crossings and loading delays. Next, machine learning algorithms identified 23 critical variables affecting delivery times. Finally, real-time tracking sensors fed live data into predictive engines.

| Metric | Traditional System | New Model | Improvement |

|---|---|---|---|

| Accuracy Window | ±8 hours | ±47 minutes | 89% tighter |

| Customer Complaints | 22/month | 5/month | 77% reduction |

| Route Adjustments | Manual | Auto-generated | 41% faster |

Integration with existing tools proved crucial. The model connected to transportation management systems through API gateways, enabling automatic driver alerts when weather risks emerged. Customers received revised ETAs via mobile apps before dispatchers made phone calls.

Scalability tests showed the solution handles 12,000 daily shipments across 38 states. Smaller carriers benefit through cloud-based versions requiring minimal IT investment. As one operations director noted: “We’re not just tracking trucks – we’re predicting possibilities.”

The industry shift toward adaptive systems creates new benchmarks. Companies achieving 92% forecast accuracy report 19% higher contract renewal rates. These solutions don’t eliminate delays – they turn uncertainty into managed variables, building trust through transparency.

Balancing Traditional AI and Generative AI Approaches

Logistics planners face a critical choice between proven methods and emerging technologies – a decision impacting 23% of annual operational costs. Established systems deliver consistent results, while novel solutions unlock untapped potential. The key lies in strategic alignment with specific business needs.

When Conventional Methods Excel

Rule-based systems thrive in stable environments. Regression models accurately forecast fuel needs for highway routes with predictable traffic. Decision trees help classify standard shipment types, ensuring 94% accuracy in warehouse scheduling. These tools form the backbone of daily operations for 78% of North American carriers.

Limitations surface when facing rapid change. A logistics manager explains: “Our tree-based system couldn’t adapt when pandemic buying patterns emerged – we manually updated rules weekly.” Traditional approaches require structured data inputs, struggling with real-time weather feeds or social media-driven demand shifts.

Next-Generation Problem Solving

Generative systems rewrite the playbook. They analyze unstructured data like port webcams or driver voice logs, spotting patterns humans miss. One European firm reduced dock congestion by 41% using machine learning that simulates loading bay scenarios. These tools self-improve, refining predictions with each completed shipment.

| Capability | Traditional | Generative |

|---|---|---|

| Data Handling | Structured only | Multiformat analysis |

| Adaptation Speed | Manual updates | Continuous learning |

| Scenario Planning | Predefined rules | Dynamic simulations |

Hybrid approaches now dominate intelligent transportation systems. A West Coast carrier combines historical regression models with generative route optimizers. This blend cut fuel costs by 18% while maintaining 99% on-time rates. As one tech lead notes: “We’re not replacing our foundation – we’re building skyscrapers on it.”

Optimizing Logistics Operations with Predictive ETA Insights

Precision timing transforms logistics from a cost center to a profit driver. Organizations using dynamic arrival insights report 22% faster dock turnarounds and 31% fewer overtime hours. These systems align workforce schedules with shipment timelines, eliminating wasted labor costs.

Improving Customer Experience through Real-Time Updates

Proactive communication builds trust in volatile environments. A leading retailer cut complaint calls by 58% after implementing automated status alerts. Clients receive revised timelines before delays affect final delivery windows.

| Factor | Traditional Approach | Predictive Insight | Impact |

|---|---|---|---|

| Labor Allocation | Fixed shifts | Demand-based staffing | 19% cost reduction |

| Detention Costs | Reactive payments | Pre-scheduled buffers | $4.8M annual savings |

| Customer Communications | Manual updates | Auto-generated alerts | 73% satisfaction boost |

Real-time tracking portals let clients monitor progress like watching a package move on a map. One chemical supplier reduced check-in calls by 82% after enabling shipper-facing dashboards. “Transparency became our differentiator,” notes their operations director.

Exception management tools flag risks before they escalate. If a truck faces unexpected delays, systems reroute backups automatically. This proactive approach maintains 94% on-time rates despite increasing supply chain complexity.

Real-World Applications and Case Studies

Global logistics leaders are rewriting delivery playbooks through adaptive arrival forecasting systems. These solutions prove their worth not in labs – but on highways, docks, and last-mile routes where minutes determine profitability.

Industry Innovations in Motion

UPS transformed its operations with the ORION platform, recalculating driver paths every 90 seconds. This dynamic optimization considers live traffic, package priorities, and fuel efficiency – saving 100 million miles annually. Drivers now avoid left turns across 55,000 routes, cutting idle time by 18%.

Uber’s DeepETA neural networks process 50 variables per trip, from bike lane availability to subway delays. Self-attention mechanisms help the system weigh factors differently in Mumbai versus Manhattan. “Our models improve predictions by learning from billions of completed trips,” explains their mobility lead.

Maritime logistics gains precision through Kpler’s vessel tracking. By blending AIS signals with historical port data, the platform forecasts arrivals within 2-hour windows – critical for coordinating crane operators and customs teams. One Asian terminal reduced demurrage fees by 37% using these insights.

DHL’s SmartTruck initiative demonstrates last-mile mastery. Integrated GPS and traffic feeds adjust routes mid-delivery, while emission tracking aligns with sustainability goals. A pilot program in Berlin achieved 94% on-time rates despite construction zones affecting 23% of routes.

These examples show how modern ETA models create ripple effects beyond timeliness. They reduce fuel waste, improve labor allocation, and turn delivery data into competitive assets. As one logistics director notes: “We’re not just moving boxes – we’re orchestrating certainty.”

Addressing Challenges and Implementing Best Practices

Even robust models stumble when GPS signals vanish near mountain ranges or urban canyons. One carrier lost 14% of location updates crossing the Rockies until implementing multi-source validation. These gaps highlight why adaptive systems need layered data streams – cellular triangulation when satellites fail, driver check-ins during blackout zones.

Building Trust in Disconnected Systems

Merging legacy tools with modern solutions requires surgical precision. A West Coast distributor spent 11 months aligning warehouse scanners with their new prediction engine. The breakthrough came through API middleware that translated 12 different timestamp formats into universal UTC.

When Algorithms Meet Human Judgment

No model predicts riots blocking Chilean ports. That’s why leading firms pair automated alerts with escalation protocols. During the 2023 Canadian wildfires, a logistics team rerouted 38 trucks within hours – their system flagged at-risk routes while managers negotiated alternative carriers.

Successful implementations balance ambition with pragmatism. Start with high-impact corridors before expanding network-wide. Validate etas against ground truth weekly. As one operations VP notes: “Perfection paralyzes – progress comes through iterative refinement.”

FAQ

Why are accurate ETAs critical for supply chain efficiency?

Precise estimated time arrivals reduce delays, optimize inventory planning, and improve customer trust. Companies like DHL and UPS rely on real-time data to minimize disruptions—ensuring smoother operations and cost savings across transportation networks.

How does machine learning improve ETA predictions compared to traditional methods?

Traditional approaches often use static schedules or basic GPS tracking. Machine learning models analyze variables like traffic patterns, weather shifts, and historical shipment trends dynamically. This enables adaptive predictions that adjust to real-time changes in vessel speed or route conditions.

What data sources are essential for building reliable predictive models?

High-quality inputs include GPS tracking for location accuracy, weather APIs for storm forecasts, traffic sensors for congestion patterns, and historical logistics data. Platforms like Uber Freight integrate these sources to refine delivery window accuracy.

Can generative AI enhance predictive ETA solutions in logistics?

While traditional models excel at structured data analysis, generative AI can simulate complex scenarios—like port congestion or sudden demand spikes—to stress-test predictions. Combining both approaches balances reliability with innovation.

How do companies like UPS handle unexpected delays in their ETA systems?

UPS employs machine learning algorithms that reroute shipments in real time. By processing live traffic updates and weather alerts, their systems automatically adjust delivery timelines, maintaining customer satisfaction despite disruptions.

What challenges arise when integrating predictive ETA tools into existing logistics workflows?

Data silos and legacy systems often hinder seamless adoption. Successful implementation requires cleaning historical data, standardizing formats, and training teams to interpret predictive insights—steps FedEx took to boost on-time delivery rates by 18%.

How do real-time updates impact customer experience in freight logistics?

Proactive notifications about delays or route changes build transparency. For example, Maersk’s tracking portal uses predictive ETAs to keep clients informed, reducing inbound queries by 30% and strengthening long-term partnerships.