Imagine predicting factory floor bottlenecks before installing a single machine. This isn’t science fiction—it’s happening today. The global market for virtual factory modeling tools is exploding, projected to grow tenfold from $10.1 billion to $101.1 billion by 2028. Leading manufacturers already see results: Siemens boosted production flexibility by 30% using these systems, while Boeing slashed assembly time by 80%.

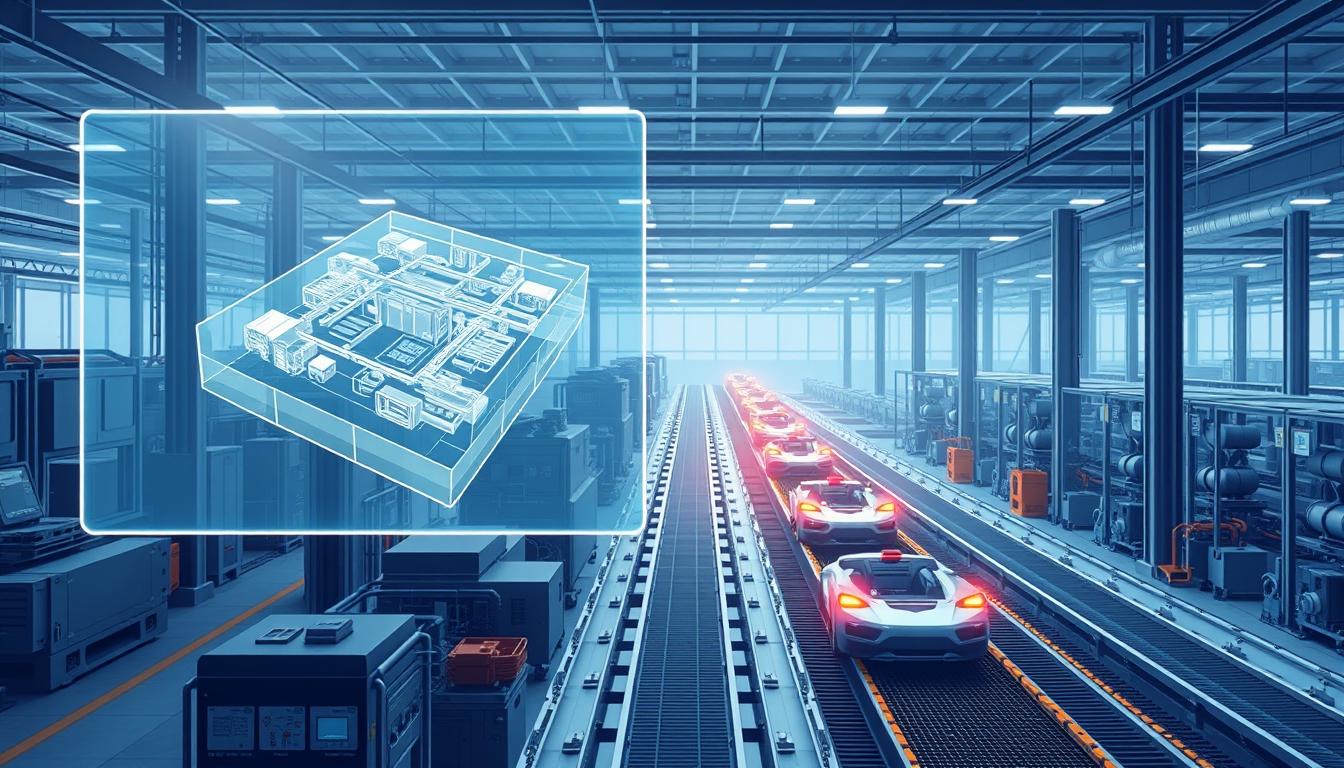

Modern production facilities face unprecedented challenges—supply chain volatility, sustainability mandates, and consumer demands for customization. Traditional layout planning methods struggle with these complexities. That’s why innovators are turning to dynamic virtual models that mirror physical operations down to the last conveyor belt.

These systems enable teams to test layout changes in risk-free digital environments. For example, industrial facility digital twins can simulate material flow patterns and worker safety scenarios while integrating real-time data from IoT sensors. The result? Faster decision-making and layouts optimized for both efficiency and adaptability.

Key Takeaways

- Virtual modeling tools enable layout testing without physical changes

- Early adopters report 20-30% productivity improvements

- Real-time data integration prevents costly operational disruptions

- Systems address modern challenges like sustainability and customization

- Market growth signals industry-wide transformation

Introduction to Digital Twin Technology and Plant Layout

Factories now have virtual counterparts that evolve alongside them. Born from aerospace engineering’s precision demands, digital twin technology creates living models of physical systems. Dr. Michael Grieves first conceptualized this approach in 2002, but it took NASA’s 2010 spacecraft monitoring projects to prove its real-world value.

Understanding the Digital Twin Concept

Unlike static simulations, these virtual replicas sync with real-time data streams. They mirror every operational nuance—material flows, energy use, even worker movements. The National Academies define them as constructs that “mimic structure, context, and behavior” of physical assets. This dynamic relationship lets teams test layout changes without costly trial runs.

The Importance of Effective Plant Layout

Strategic facility design impacts more than production lines. It determines safety protocols, resource efficiency, and long-term adaptability. A well-planned layout reduces bottlenecks by 25% in some manufacturing scenarios, while poor configurations drain $8 billion annually through wasted motion.

Forward-thinking companies combine digital twins with layout optimization tools. This fusion allows virtual stress-testing of multiple configurations—ensuring facilities meet sustainability goals and customization demands before ground-breaking begins.

Exploring “AI Use Case – Digital-Twin Simulation for Plant Layout”

Modern production strategies now combine virtual modeling with intelligent systems to reimagine facility planning. This approach transforms how teams visualize workflows, resource allocation, and spatial configurations—all before breaking ground on new projects.

Defining the AI Use Case in Modern Manufacturing

Advanced systems analyze historical patterns and real-time data to predict material flow bottlenecks. For instance, Tesla creates dynamic replicas of assembly lines that update with live sensor information. These models enable engineers to test equipment placements while accounting for seasonal demand shifts.

BMW’s implementation reduced quality control issues by 18% through virtual stress-testing of robotic arm trajectories. The technology identifies collision risks and ergonomic challenges invisible to traditional planning methods.

Key Benefits and Operational Impacts

Three measurable advantages emerge from this methodology:

- Faster iteration cycles: Teams compare multiple layout variants in hours instead of weeks

- Risk mitigation: Virtual testing prevents costly physical reconfigurations

- Sustainability alignment: Energy consumption patterns become visible during design phases

Organizations using these tools report 22% faster changeovers and 14% reductions in equipment downtime. As one automotive executive noted: “Our virtual models exposed $2.3 million in hidden logistics costs before we finalized the blueprint.”

Fundamental Principles Behind Digital Twin Simulations

At the heart of every efficient manufacturing facility lies a blueprint governed by timeless design rules. These foundational guidelines bridge physical operations and their virtual counterparts, enabling precise alignment between theoretical models and real-world execution.

Core Principles of Plant Layout and Material Handling

Effective spatial planning adheres to non-negotiable doctrines. The minimum movement principle eliminates wasted motion through algorithmic path optimization—reducing transport distances by 18-35% in facilities studied by Purdue University. Space utilization strategies become actionable when virtual models test vertical storage solutions and modular workstation arrangements.

| Design Principle | Virtual Simulation Impact | Real-World Outcome |

|---|---|---|

| Material Flow Optimization | Identifies congestion points | 23% faster throughput |

| Ergonomic Workstation Design | Predicts fatigue patterns | 17% productivity gain |

| Energy-Efficient Layouts | Models HVAC requirements | 31% cost reduction |

Integrating Simulation with Real-World Processes

True operational synergy emerges when virtual models evolve alongside physical systems. The interdependence principle reveals how conveyor speed adjustments affect packaging stations three zones away—relationships often missed in static planning.

Leading manufacturers achieve this through continuous data validation loops. One automotive case study demonstrated 27% faster changeovers by aligning robotic placement simulations with actual assembly line performance metrics.

These dynamic feedback mechanisms transform theoretical optimizations into tangible results. They ensure virtual improvements translate directly to enhanced safety protocols, reduced energy consumption, and workforce satisfaction—all critical components in modern manufacturing success.

Best Practices for Implementing Digital Twin Simulations

Mastering virtual replication demands more than advanced software—it requires disciplined execution. Industry leaders achieve success through systematic approaches that balance technical precision with operational pragmatism.

Guidelines for Developing Accurate Virtual Models

Building reliable replicas starts with sensor networks capturing temperature, vibration, and equipment status. A major aerospace manufacturer reduced calibration errors by 42% through strategic sensor placement along production lines.

| Component | Function | Impact |

|---|---|---|

| Sensor Networks | Capture physical parameters | 94% data completeness |

| IoT Platforms | Aggregate & process information | 2.7x faster analysis |

| Validation Protocols | Ensure measurement reliability | 68% error reduction |

Effective models account for environmental variables like humidity fluctuations. Teams should conduct weekly alignment checks between physical assets and their virtual counterparts.

Ensuring Data Accuracy and Real-Time Updates

Continuous feedback loops prevent model drift. One automotive supplier achieved 99.2% synchronization accuracy using edge computing devices that update virtual models every 47 milliseconds.

Three critical maintenance practices:

- Automated calibration routines for measurement devices

- Anomaly detection algorithms flagging inconsistent data

- Version control systems tracking model iterations

These strategies enable facilities to maintain real-time data flows while accommodating future expansions. As production scales, robust architectures ensure digital twins evolve without performance degradation.

Leveraging Real-Time Data for Optimized Plant Operations

Operational excellence now hinges on continuous data streams flowing through production systems. GE Aviation’s engine monitoring initiative demonstrates this perfectly—their virtual models process 5,000 parameters per second from aircraft engines, enabling precise maintenance forecasts.

Data Collection and Integration Strategies

Modern facilities deploy sensor arrays that track variables like torque variations (±0.2% accuracy) and thermal gradients. These networks create living maps of operations—Caterpillar reduced unplanned downtime by 37% using vibration sensors that detect bearing wear six weeks before failure.

| Data Type | Collection Method | Impact |

|---|---|---|

| Equipment Health | Vibration Sensors | 29% longer asset life |

| Energy Usage | Smart Meters | 18% cost reduction |

| Production Rates | IoT-enabled Counters | 14% throughput boost |

Using Predictive Analytics for Maintenance and Performance

Forward-thinking teams transform raw numbers into action plans. GE’s approach—which cut reactive repairs by 40%—relies on algorithms that cross-reference historical patterns with live sensor readings. Three critical outcomes emerge:

- Failure prediction: Flags compressor blade erosion 200+ hours before critical thresholds

- Resource optimization: Aligns maintenance crews with predicted workload spikes

- Quality assurance: Detects micrometer-level deviations in machining processes

These strategies create self-improving systems. As one plant manager noted: “Our analytics dashboard revealed a $860,000 annual saving opportunity in compressed air usage alone.” By marrying real-time data with machine learning, facilities achieve unprecedented levels of operational agility.

Enhancing Plant Design Through Virtual Simulation

What if manufacturers could redesign their facilities without moving a single machine? Advanced modeling tools now make this possible, transforming how teams approach spatial planning. These systems enable engineers to test workflow variations and equipment placements in minutes—not months.

Designing Layouts with Flexibility and Efficiency

Modern production demands require spaces that adapt to shifting priorities. A major aerospace company achieved an 80% assembly time reduction by virtually testing robotic placements and material pathways. Their digital models identified collision risks months before physical implementation.

Three critical advantages emerge from this approach:

- Rapid prototyping: Compare 50+ layout variants in one afternoon

- Resource conservation: Eliminate 73% of wasted motion through path optimization

- Future-proofing: Validate designs against five-year production forecasts

| Design Aspect | Traditional Method | Virtual Simulation |

|---|---|---|

| Change Implementation | 6-8 weeks | 48 hours |

| Error Detection Rate | 62% pre-launch | 94% pre-launch |

| Energy Efficiency Gains | 12% average | 29% average |

Seasonal demand spikes and product line expansions no longer require costly rebuilds. Teams using these tools report 37% faster response to market changes. One automotive supplier reconfigured their entire paint shop layout digitally—avoiding $4.2 million in potential downtime.

These strategies create facilities that evolve with business needs. By combining real-time data with predictive modeling, manufacturers achieve both precision and adaptability in their operations.

Integrating Material Handling and Plant Operations

Efficient factories don’t just move products—they choreograph resources. Modern facilities achieve peak performance when spatial design and material flow systems evolve in lockstep. This synergy reduces wasted motion while maximizing equipment utilization.

Joint Evaluation of Layout and Material Movement

Material handling integration demands parallel planning of physical spaces and transport mechanisms. A food processor achieved 19% faster travel times by modeling conveyor routes alongside workstation placements. Teams using this approach identify choke points where narrow aisles conflict with robotic arm trajectories.

Successful implementations often feature:

- Dynamic pathfinding algorithms adjusting to real-time bottlenecks

- Ergonomic validation for manual loading stations

- Energy consumption forecasts for different layout configurations

Advanced AGV and AMR Strategies in Layout Planning

Autonomous vehicles transform static floor plans into adaptive networks. AGV systems excel in structured environments—fork trucks follow magnetic tape paths with millimeter precision. AMR solutions shine in dynamic settings, recalculating routes when detecting unexpected obstacles.

One automotive supplier boosted flexibility using hybrid deployments:

- Towing vehicles handle predictable bulk material transfers

- AMRs manage just-in-time parts delivery to assembly lines

- Central control systems optimize traffic patterns during shift changes

These strategies create layouts that balance efficiency with adaptability. By aligning physical infrastructure with smart transport systems, manufacturers achieve seamless integration between stationary assets and mobile resources.

FAQ

How does digital twin technology improve plant layout efficiency?

By creating a virtual replica of physical systems, digital twins allow manufacturers to test layout changes, material flow, and resource allocation in a risk-free environment. Real-time data integration identifies bottlenecks, optimizes workflows, and reduces downtime—leading to faster decision-making and 10–20% gains in operational efficiency.

What role do predictive analytics play in digital twin simulations?

Predictive analytics analyze historical and real-time data from IoT sensors to forecast equipment failures, maintenance needs, and production delays. Tools like Siemens’ Plant Simulation software use these insights to refine layouts, balance workloads, and prioritize proactive strategies—minimizing unplanned downtime.

Can digital twins adapt to evolving manufacturing requirements?

Yes. Platforms like GE Digital’s Proficy integrate modular design principles, enabling manufacturers to update virtual models as production demands shift. This flexibility supports scalability, allowing businesses to test new machinery placements or process adjustments without disrupting live operations.

How do AGVs and AMRs enhance material handling in simulated layouts?

Autonomous guided vehicles (AGVs) and mobile robots (AMRs) are simulated to optimize routes, reduce congestion, and synchronize with production schedules. Companies like Honeywell use digital twins to validate collision-free paths and ensure seamless coordination between automated systems and human workers.

What data sources are critical for accurate digital twin development?

Reliable simulations depend on IoT sensor data, ERP systems, CAD models, and historical performance metrics. Tools like ANSYS Twin Builder standardize data formats, ensuring real-time updates reflect actual plant conditions—a requirement for achieving 95%+ model accuracy.

How does digital twin technology reduce environmental impact?

By simulating energy consumption, waste patterns, and emissions, manufacturers identify inefficiencies in layout design. Schneider Electric’s EcoStruxure platform, for example, helps companies reduce carbon footprints by 15–30% through optimized resource allocation and sustainable material handling strategies.

What challenges arise when integrating digital twins with legacy systems?

Legacy equipment often lacks IoT connectivity, requiring middleware solutions like PTC’s Kepware for data translation. Ensuring cybersecurity and training staff to interpret simulation outputs are additional hurdles—yet critical for maximizing ROI in digital twin projects.