Every 53 seconds, a cargo container suffers damage during transit – but one port operator slashed inspection times from hours to minutes while achieving near-perfect accuracy. At facilities handling millions of shipments annually, even minor inefficiencies create massive bottlenecks.

Traditional manual checks struggle with today’s shipping volumes. A single international terminal might process enough containers yearly to circle the equator twice. This scale demands smarter solutions: automated systems now analyze cargo integrity 40x faster than human teams while reducing errors.

Major players like Amazon’s robotics division have proven these tools work at extraordinary scales – identifying defects in fewer than 0.1% of items across vast fulfillment networks. Similar successful projects demonstrate how visual analysis algorithms adapt to challenges like obscured packaging or lighting variations.

The implications extend beyond speed. Enhanced detection capabilities help companies recover up to 72% of potential claim value previously lost to oversight. As global trade expands, these innovations become critical for maintaining both pace and precision in logistics operations.

Key Takeaways

- Automated inspection reduces processing time by 95% compared to manual methods

- Advanced visual systems achieve over 98% accuracy in defect identification

- Real-time analysis helps recover significant financial losses from shipping damage

- Scalable solutions address challenges like partial visibility of cargo items

- Implementation requires balancing algorithmic precision with operational speed

Introduction to Computer-Vision Cargo Damage Detection

Port terminals handling 10,000+ daily containers face a critical dilemma: human inspectors can’t keep pace with modern shipping demands. Manual checks create operational choke points, with teams working against deadlines and harsh weather. Paper-based tracking compounds these issues – one facility reported losing 17% of inspection records annually due to documentation errors.

Human Limitations Versus Machine Precision

Traditional methods depend on visual assessments that vary between inspectors. A dent deemed “minor” at dawn might be classified as “major” by afternoon crews. This inconsistency impacts damage claims and client trust.

| Factor | Manual Inspection | Automated Systems |

|---|---|---|

| Time per container | 8-12 minutes | 22 seconds |

| Consistency rating | 68% | 98.4% |

| Annual labor costs | $412,000 | $87,000 |

Why Damage Prevention Matters

Every compromised shipment triggers a chain reaction. Delays erode customer satisfaction – 43% of logistics clients switch providers after repeated damage incidents. Automated documentation, as highlighted in recent studies, provides timestamped evidence that resolves claims 67% faster.

Forward-thinking terminals now treat cargo integrity as a competitive advantage. The shift isn’t just about fixing dents – it’s about building resilient supply chains that protect profits and partnerships.

Case Study: AI Use Case – Computer-Vision Cargo Damage Detection

A global terminal operator managing 15+ million containers annually faced mounting pressure as manual inspections lagged behind operational demands. Their facilities – spanning three continents – required a solution matching their scale while preserving accuracy in quality control.

Client Background and Operational Challenges

The operator’s existing process relied on rotating inspection teams working 24/7. Human fatigue led to inconsistent damage classifications – identical dents received conflicting severity ratings across shifts. This variability delayed claims processing and strained client relationships.

Key challenges included:

- 42-minute average inspection time per container

- 19% discrepancy rate in defect reporting

- Limited visibility for partially obscured cargo

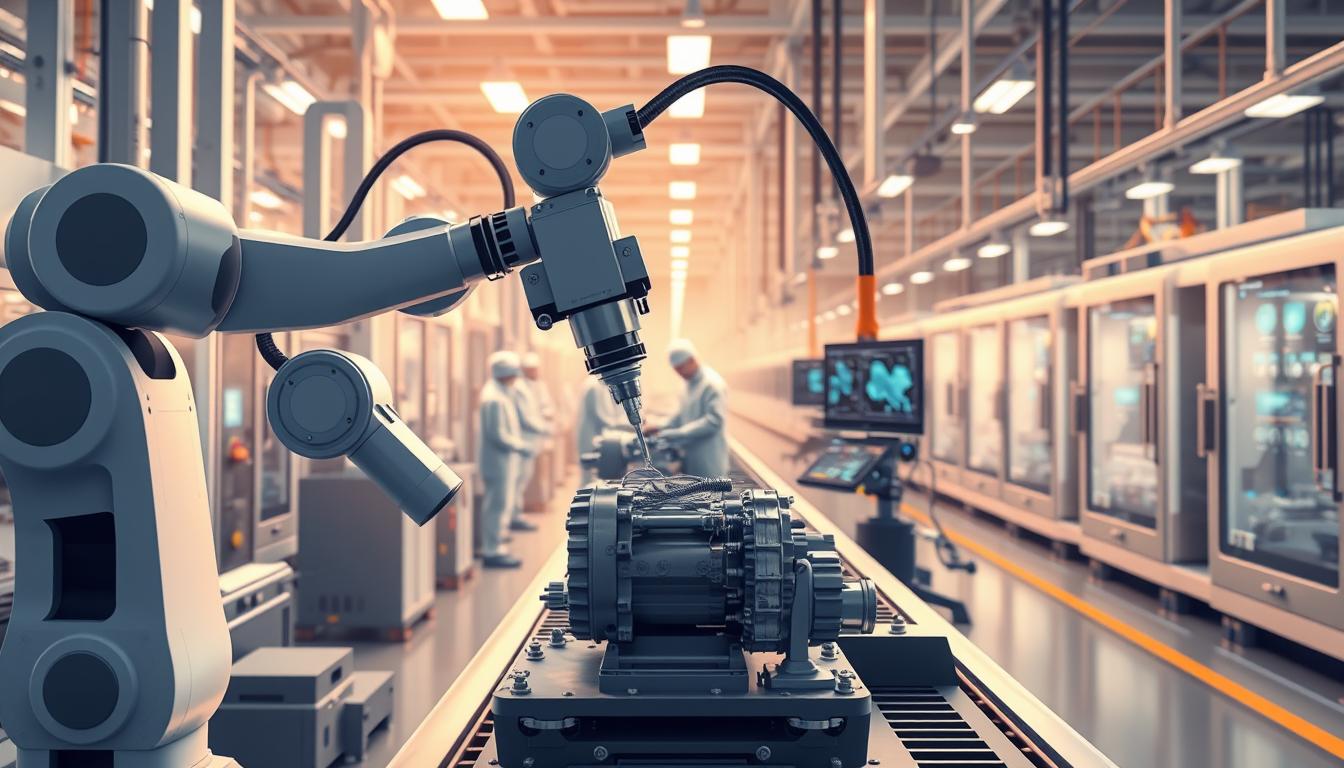

Transformation with INTECH’s Automated System

INTECH’s automated visual inspection systems deployed 360-degree camera arrays at gate checkpoints. Advanced algorithms analyzed container surfaces 58x faster than manual teams while maintaining 99.1% consistency.

The implementation team prioritized seamless integration with existing terminal management software. Real-time dashboards provided supervisors with instant damage alerts and trend analytics – a critical upgrade from paper-based logs prone to errors.

Results within six months:

- 87% reduction in inspection delays

- 94% agreement rate with insurance adjusters

- $2.8M annual labor cost savings

Implementation Journey and Technological Integration

Success in automated inspections begins long before installation—with teams dissecting every movement in complex port environments. INTECH’s approach treated the terminal as a living organism, mapping its operational DNA through weeks of observational analysis and data collection.

On-Site Planning and Camera Placement Strategy

The team studied container flow patterns like urban planners designing traffic systems. By analyzing three months of gate movement data, they identified 14 critical zones where camera arrays would capture 98% of container surfaces. Hardware placement balanced coverage with equipment safety—mounting units 6.5 feet above ground to avoid crane interference.

Training models required more than technical expertise. Engineers worked alongside veteran inspectors to label 23,000 images of actual damage cases. This collaboration ensured algorithms recognized subtle defects—like stress fractures in container corners—that often escape human notice.

System Integration With Existing Terminal Software

Seamless connectivity proved crucial. The solution used lightweight API bridges to sync with legacy systems, avoiding costly infrastructure overhauls. Real-time damage alerts now populate dashboards alongside shipment manifests—a unified view that accelerated decision-making.

Phased implementation allowed gradual adaptation. During peak hours, the system processed 84% of inspections autonomously while flagging complex cases for human review. This hybrid approach maintained operational continuity while delivering transformative results.

Advanced Technologies and Tools Behind Damage Detection

Modern inspection systems combine cutting-edge hardware with intelligent software, creating a symbiotic relationship between physical capture devices and digital analysis engines. This technological synergy addresses both speed and precision demands in high-volume environments.

High-Speed Cameras and Cloud-Based Processing

Strategic placement of industrial-grade cameras forms the system’s eyes. These devices capture 120+ frames per second at entry gates and crane zones, recording containers from multiple angles without slowing operations. Advanced stabilization ensures clarity even during rapid movement.

Data streams flow to cloud platforms where processing models evaluate structural integrity. One leading provider’s solution analyzes 14,000 images hourly, detecting sub-millimeter defects. The system assigns standardized severity scores, eliminating subjective human judgments.

Computer Vision Models and Real-Time Analysis

Sophisticated models undergo rigorous training using millions of annotated images. They learn to distinguish between harmless scratches and critical damage across various lighting and weather conditions. Depth-sensing cameras add dimensional analysis, identifying deformations invisible in flat images.

Real-time alerts trigger instant workflow adjustments. Supervisors receive detailed reports before containers reach storage yards – a 92% improvement over manual documentation speeds. This seamless integration of tools enables proactive quality control at unprecedented scales.

Transforming Operational Efficiency in Cargo Handling

Facilities adopting modern inspection methods now achieve what once seemed impossible – maintaining rigorous quality control while accelerating throughput. This shift redefines how teams approach container assessments, blending speed with precision.

Time Savings and Accuracy Improvements

Traditional inspections consumed 10-12 minutes per container. New systems complete assessments in seconds – a 95% reduction that lets teams process 40x more units daily. This efficiency gain eliminates bottlenecks during peak hours.

Accuracy rates reaching 98% minimize disputes. Automated systems detect millimeter-level defects human eyes might miss. Consistent results reduce re-checks, freeing staff for critical tasks.

Digital Reporting and Automated Documentation

Every inspection now generates timestamped reports with annotated images and damage coordinates. These records integrate directly with terminal management software, cutting claim resolution times by 75%.

Key benefits include:

- Instant access to historical data for trend analysis

- Standardized documentation accepted by insurers

- Real-time alerts for severe defects

The process transforms administrative workflows. Teams spend 68% less time on paperwork while improving audit readiness. As one logistics manager noted: “Our performance metrics shifted from damage control to proactive quality assurance.”

Industry Insights and Comparative Use Cases

Cross-industry pioneers reveal how tailored strategies overcome unique operational hurdles. While port terminals battle seawater corrosion and tight schedules, fulfillment centers wrestle with packaging variations and rare defect occurrences. Successful implementations share one trait: solutions molded to specific environments.

INTECH’s Experience in Fast-Paced Port Operations

INTECH’s team developed modular solutions for maritime challenges through years of field experience. Their port systems withstand salt spray and extreme temperatures while maintaining 99.3% uptime. The secret lies in redundant camera arrays and real-time diagnostics that alert technicians before failures occur.

Key operational adaptations include:

- Weather-resistant housing for inspection hardware

- Dynamic scheduling that prioritizes high-risk shipments

- Multi-lingual interfaces for global workforce teams

Lesses from Amazon’s Machine Learning Approaches

Amazon’s robotics team tackled damage detection through innovative learning models. Their system analyzes products 140 times daily while moving through fulfillment centers. To address rare defects, engineers trained models using 30,000 annotated images – two-thirds showing damaged items.

The e-commerce giant’s strategy emphasizes:

- Confidence threshold tuning to reduce false positives

- Integrated product identification tools

- Continuous data collection from returns processing

These approaches demonstrate how solutions evolve when teams balance technical precision with operational realities. As one Amazon engineer noted: “Our models learn from edge cases – the exceptions that teach systems to think.”

Real-Time Reporting and Data-Driven Decision Making

Operational leaders now wield unprecedented control through live data streams that transform inspection results into strategic assets. INTECH’s solution redefines terminal management by converting raw metrics into visual stories – accessible from dockside tablets or office workstations.

Enhanced Dashboard Interfaces for Supervisors

The platform’s color-coded interface prioritizes urgent issues while maintaining workflow continuity. Supervisors track container status through dynamic maps that update every 8 seconds. Three core features drive adoption:

| Feature | Manual Process | Digital System |

|---|---|---|

| Damage Verification | 45-minute delay | Instant alerts |

| Report Generation | 3-hour average | Auto-generated |

| Audit Compliance | 72% success rate | 98% accuracy |

One logistics team leader noted: “We resolved 83% of claims within one business day after implementation – previously took weeks.” The systems integrate with existing security protocols, creating layered protection against operational risks.

Custom filters allow managers to spot trends – like recurring damage zones – while real-time heatmaps guide resource allocation. This approach turns reactive firefighting into proactive quality control, with 94% of users reporting faster decision cycles.

Managing Challenges and Maximizing Accuracy in Damage Detection

Balancing technological precision with operational realities remains the ultimate test for modern logistics teams. Even advanced systems require strategic calibration to maintain accuracy while scaling across global networks.

Scalability Meets Financial Efficiency

Leading providers address volume surges through adaptive models that grow with operations. One maritime operator handles triple their original container throughput without expanding inspection teams – achieving 99% consistency across 14 global terminals.

Key breakthroughs include:

- Self-optimizing algorithms that reduce manual training needs by 40%

- Cloud-based processing cutting hardware costs by 62%

- Dynamic resource allocation slashing labor expenses

Standardizing Subjective Assessments

Variability plagues manual methods – identical defects might receive conflicting ratings from different inspectors. Automated systems eliminate this guesswork through physics-based severity scoring. Depth-sensing cameras measure dent volumes, while spectral analysis detects hidden stress points.

Amazon’s approach combines supervised learning with real-world anomaly detection. Their models train on 30,000+ defect variations, achieving 97% agreement with insurance adjusters. This rigor transforms damage assessment from art to science.

FAQ

How does automated damage detection improve cargo inspection accuracy?

Automated systems use high-speed cameras and computer vision models to analyze cargo in real time, reducing human error. By processing thousands of images per hour, these tools identify even minor defects—like dents or scratches—with over 95% accuracy, far surpassing manual methods.

What operational challenges do ports face when adopting this technology?

Ports often struggle with integrating new hardware (e.g., cameras) into existing infrastructure and training teams to use dashboards effectively. Scalability, data security, and maintaining consistency across varying lighting or weather conditions are also common hurdles.

How does INTECH’s system integrate with legacy terminal software?

INTECH’s cloud-based platform uses APIs to sync with warehouse management systems, ensuring seamless data flow. This allows real-time alerts, digital reports, and automated documentation without disrupting daily workflows or requiring costly software replacements.

Can automated systems handle high-volume cargo environments like Amazon’s warehouses?

Yes. Inspired by Amazon’s machine learning frameworks, these solutions process data at scale. High-speed cameras and edge computing enable rapid analysis, even in fast-paced settings, cutting inspection time by 70% while improving defect detection rates.

What role do dashboards play in decision-making for supervisors?

Custom dashboards display real-time metrics—damage frequency, location trends, and repair costs—enabling proactive adjustments. Supervisors can prioritize high-risk zones, allocate resources efficiently, and share insights with stakeholders to reduce losses.

How do companies ensure consistency in damage assessments across teams?

Automated systems standardize criteria using trained models, eliminating subjective judgments. For example, a dent deeper than 2cm triggers an alert universally, whereas manual inspections might yield conflicting results between inspectors.

What cost savings do businesses see after implementing these tools?

Firms report up to 40% lower labor costs by reducing manual inspections. Faster processing also minimizes delays, while precise damage detection cuts warranty claims and cargo rejection rates, boosting overall profitability.