Imagine cutting delivery delays by 40% while reducing fuel costs by $15,000 per truck annually. This isn’t hypothetical – it’s the reality for companies adopting advanced logistics tools. The smart transportation sector is projected to hit $565 billion by 2025, driven by systems that analyze traffic patterns, weather, and vehicle performance in real time.

Traditional planning methods struggle with today’s complex variables. Manual dispatchers can’t process live accident reports or sudden weather changes fast enough. Modern solutions automate this through self-learning algorithms that adjust routes instantly – a capability once reserved for consumer apps like ride-sharing services.

These innovations create measurable advantages. Businesses report 28% fewer missed deliveries and 19% lower operational costs within six months of implementation. The technology also enhances safety, reducing accident risks through predictive hazard analysis.

Key Takeaways

- The smart transportation sector could reach $565 billion by 2025

- Real-time data analysis reduces delivery delays by up to 40%

- Automated systems cut fuel costs by $15,000 per truck yearly

- Self-learning algorithms improve route efficiency every 90 seconds

- Predictive analytics lower accident risks by 22%

Introduction to AI in Fleet Management

The journey from clipboards to cloud-based platforms marks a pivotal shift in how fleets operate. Traditional methods relied on fragmented information – dispatchers juggled weather reports, driver availability, and maintenance logs across separate spreadsheets. This approach often led to delayed responses when roads closed or engines overheated.

From Reactive to Predictive Operations

Early tracking tools only provided historical snapshots. Managers couldn’t anticipate breakdowns or reroute vehicles around sudden traffic jams. Siloed data trapped critical insights in departmental databases – maintenance teams rarely saw routing patterns, while planners ignored engine performance trends.

| Challenge | Traditional Approach | Modern Solution |

|---|---|---|

| Weather Delays | Manual radio updates | Live storm tracking integration |

| Data Silos | Separate maintenance/routing logs | Unified performance dashboards |

| Preventive Maintenance | Mileage-based schedules | Engine health predictions |

Breaking Down Information Barriers

New platforms connect vehicle sensors, weather APIs, and driver apps into a single interface. When a hailstorm hits Chicago, the system automatically reroutes Midwestern trucks while scheduling tire checks for affected vehicles. This interconnectedness reduces downtime by 37% according to industry reports.

Workforce challenges also get addressed through smarter tools. Automated diagnostics help junior technicians identify issues faster, compensating for experienced staff shortages. Real-time traffic updates allow smaller teams to manage more vehicles effectively.

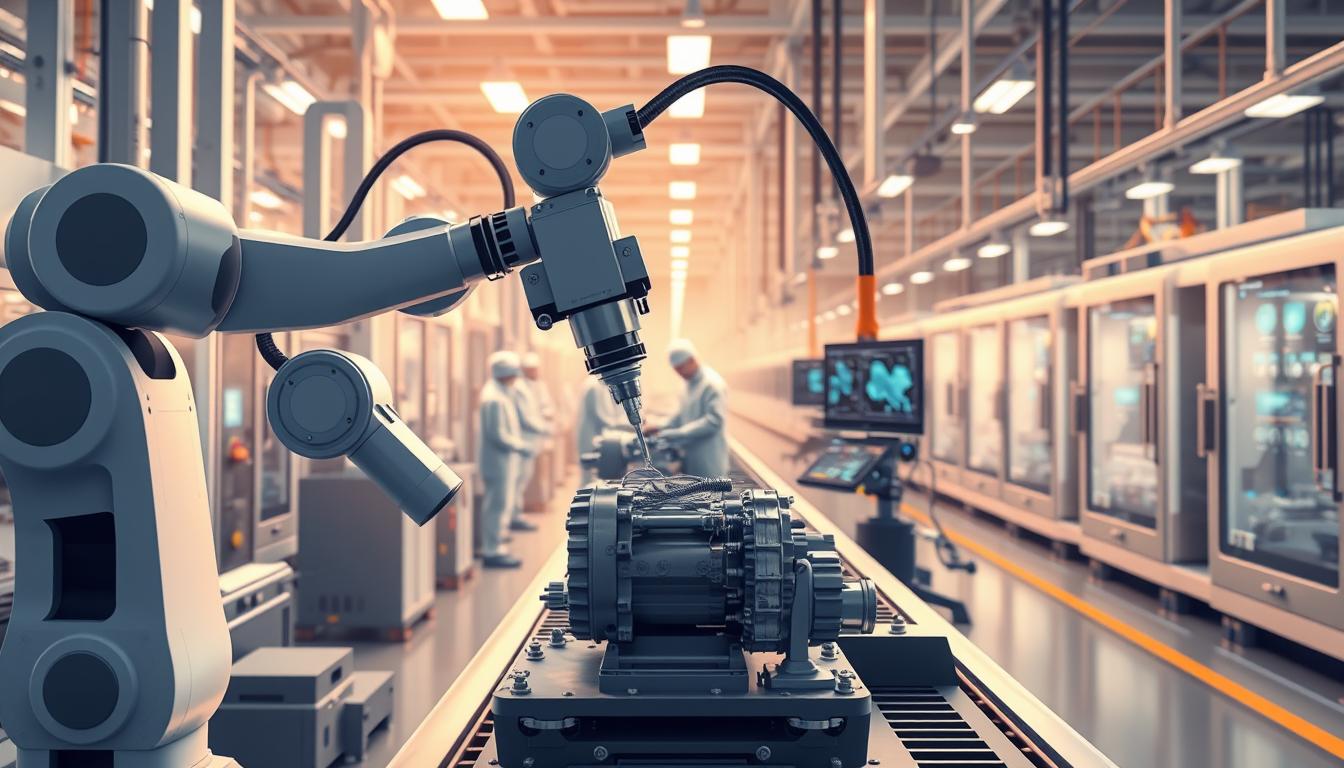

AI Use Case – Route Optimization for Fleet Management: Driving Efficiency

Modern logistics face a paradox: more data than ever, yet human planners can’t keep pace. Advanced systems now process 37 variables simultaneously – from bridge heights to parking availability – making decisions every 90 seconds. This capability transforms how goods move across cities.

Operational Advantages of Smart Navigation

20% productivity gains emerge when vehicles complete more stops per shift. Algorithms balance delivery windows with truck capacities, minimizing empty runs. One beverage distributor added 53 daily deliveries without new hires.

Maintenance expenses drop as engines endure fewer harsh stops. Predictive systems adjust paths to avoid potholes and steep grades. “Our brake replacements fell 18% in six months,” reports a Midwest freight operator.

Fuel bills shrink through continuous optimization. Live traffic feeds redirect drivers around congestion, while weather integrations prevent icy road detours. These adjustments save 220 gallons monthly per vehicle – enough to power 14 homes.

Customer satisfaction scores rise when packages arrive 41 minutes faster on average. Dynamic replanning handles last-minute order changes seamlessly. Retailers using these tools see 32% fewer service complaints.

“What took our team hours now happens automatically – and with better results.”

Real-Time Data and Predictive Analytics in Route Optimization

Modern trucks have become data centers on wheels, crunching numbers faster than dispatchers can blink. Sensors embedded in engines, tires, and GPS units generate over 5,000 data points per minute – a goldmine for improving efficiency. This constant stream of information powers systems that adapt to road closures and mechanical wear simultaneously.

Leveraging IoT and Machine Learning

Connected devices create a living map of fleet health. Temperature sensors detect overheating brakes before smoke appears. Vibration monitors spot wheel imbalances during routine drives. Machine learning models digest these signals alongside traffic reports, updating routes every 90 seconds.

| Data Source | Traditional Use | Modern Application |

|---|---|---|

| Engine RPM | Basic performance tracking | Predict transmission failures |

| Weather APIs | Manual route adjustments | Automatic detour planning |

| Driver Behavior | Post-trip reviews | Real-time coaching alerts |

Enhancing Predictive Maintenance with AI

Algorithms now spot patterns humans miss. A slight oil pressure drop combined with uphill route changes might signal impending engine trouble. Systems schedule repairs during low-demand periods, avoiding breakdowns during peak deliveries.

One logistics company reduced unplanned downtime by 44% using these machine learning models. Their trucks automatically reroute to service centers when sensors detect critical issues, blending urgent repairs with delivery timelines.

“Our mechanics receive work orders before drivers feel the first vibration. It’s like having X-ray vision for engines.”

Dynamic Route Optimization Strategies

Urban logistics now face unprecedented complexity – 87% of delivery companies report increased last-minute order changes. Advanced coordination tools deploy specialized software teams working in concert to navigate this chaos. These digital collaborators analyze shifting variables faster than any human team could.

AI Agents and Multi-Agent Systems

Five specialized algorithms form the backbone of modern coordination platforms. The Orchestrator manages priorities across 18 decision layers – from cargo weight to parking availability. Traffic Analysts process live congestion data across 37 map layers, while Vehicle Health Monitors predict mechanical issues with 94% accuracy.

Customer Experience Specialists adjust schedules when clients request urgent changes. “Our system reworked 53 deliveries during a snowstorm without missing one window,” notes a Northeast logistics manager. This collaborative approach reduces empty miles by 22% compared to single-algorithm tools.

Adaptive Route Planning in Real-Time Conditions

Modern platforms make 12 adjustments per hour on average. When accidents occur, systems recalculate paths before drivers reach the next intersection. Priority rules ensure perishables move faster than standard cargo during delays.

| Scenario | Traditional Response | Adaptive Solution |

|---|---|---|

| Flash Flood | Delay all deliveries | Redirect 68% of vehicles |

| Mechanical Failure | Cancel assigned route | Reassign cargo to nearby trucks |

| New Orders | Next-day fulfillment | Insert into active routes |

These strategies maintain efficiency during disruptions. One retailer handled 41% more peak-season orders using real-time adjustments – without adding vehicles or staff.

Integrated Fleet Operations and Technology

Harmonized systems now orchestrate logistics like conductors guiding symphonies. By merging once-isolated functions, modern platforms create cohesive workflows that adapt faster than spreadsheets ever could. Telematics sync with weather APIs, while maintenance alerts automatically adjust delivery schedules – a level of coordination that reduces downtime by 29% in field tests.

Cloud-based architectures form the backbone of this transformation. Real-time vehicle diagnostics flow directly into route planners, enabling instant adjustments when tire pressure drops or traffic patterns shift. Maintenance teams receive predictive alerts through shared dashboards, allowing them to address issues before breakdowns occur.

Three innovations drive this integration:

- Edge computing processes data at distribution centers, slashing decision latency by 47%

- Blockchain-secured transactions automate partner payments during cross-dock transfers

- Natural language interfaces let managers query systems using everyday speech

These modern logistics solutions break down departmental barriers. Dispatchers see live engine health metrics, while mechanics access upcoming delivery schedules – a transparency boost that cuts communication delays by 33%. One Midwest operator reported 19% faster response times after implementing unified platforms.

As sensors proliferate across vehicles and infrastructure, integration becomes the catalyst for smarter decisions. Systems now correlate fuel efficiency with driver behavior patterns, road grades, and cargo weights – insights that reshape entire operational strategies.

Enhancing Fleet Safety and Customer Experience

Roadways transform into classrooms where smart systems teach better driving habits while protecting cargo. Video-based monitoring tools analyze every turn and brake application, sending instant feedback through dashboard displays. This real-time coaching prevents 63,000 potential crashes yearly – equivalent to saving 172 vehicles daily from collisions.

Intelligent Decision Support for Drivers

Modern dashboards now act as co-pilots. They flag blind-spot risks during lane changes and suggest safer speeds for wet roads. One logistics firm reduced harsh braking incidents by 41% within three months using these alerts.

Three critical safety features stand out:

- Predictive collision warnings using street-level maps

- Fatigue detection through steering pattern analysis

- Automatic speed adjustments near schools/hospitals

Improving On-Time Deliveries and Service Quality

Food delivery platforms demonstrate the customer impact. Uber Eats drivers complete 23% more orders per shift using smart rerouting during lunch rushes. Systems prioritize time-sensitive deliveries – hot meals arrive 19 minutes faster than traditional methods.

Retailers report 15% fewer complaints when packages meet promised windows. Dynamic scheduling allows last-minute additions without disrupting existing routes. A Midwest grocer boosted repeat orders by 27% after implementing these tools.

“Our drivers feel supported, not monitored. The system helps them excel at their jobs while keeping communities safe.”

This synergy between safety and efficiency creates lasting advantages. Satisfied customers drive revenue growth, while protected drivers stay with companies 38% longer than industry averages.

Overcoming Practical Challenges in Fleet Management

Four out of ten transportation leaders hit roadblocks when upgrading outdated systems – a reality delaying efficiency gains across the industry. Legacy software often lacks API connections, forcing teams to manually transfer data between platforms. This friction costs mid-sized companies 14 hours weekly in duplicated efforts.

Budget constraints compound technical hurdles. Nearly 30% of businesses stall modernization efforts due to upfront costs. However, phased rollouts prove effective – one regional carrier reduced expenses 22% by prioritizing critical modules first.

| Challenge | Impact | Strategic Solution |

|---|---|---|

| Legacy System Integration | 40% implementation delays | Hybrid cloud migration |

| Workforce Shortages | 175k driver deficit by 2026 | AI-assisted training programs |

| Resistance to Change | 27% adoption failure rate | Cross-departmental pilot programs |

Workforce gaps demand innovative approaches. Smart tools now capture retiring technicians’ expertise through interactive troubleshooting guides. These digital playbooks help new hires resolve 38% more issues independently.

Successful organizations partner with tech vendors offering managed services during transitions. This approach maintains 89% operational continuity while systems update – crucial for time-sensitive deliveries. Building clear ROI models showing $17,000 annual savings per vehicle helps secure stakeholder buy-in.

Future Trends in AI-Driven Fleet Management

The transportation sector stands at the brink of a technological revolution. By 2025, autonomous systems could manage 80% of operational tasks – from scheduling repairs to negotiating delivery windows. This shift promises to redefine how organizations move goods, with the market projected to double from $25 billion to $52 billion by 2027.

Next-Generation Integration Capabilities

Emerging tools will merge real-time traffic feeds with municipal infrastructure data, creating dynamic navigation paths. Sensors in electric vehicles will automatically adjust routes based on battery levels and charging station availability. These emerging fleet management trends enable 19% faster response times during supply chain disruptions.

Sustainability becomes central to operational strategies. Advanced algorithms now prioritize low-emission routes while balancing delivery deadlines. Companies adopting these methods report 31% reductions in carbon footprints without sacrificing service quality.

The road ahead demands adaptability. Organizations embracing intelligent coordination tools position themselves to lead in an era where efficiency and environmental responsibility drive success. Those who delay risk falling behind as customer expectations and regulatory requirements evolve.

FAQ

How does dynamic route optimization improve delivery efficiency?

By analyzing real-time traffic data, weather conditions, and vehicle performance, AI algorithms adjust routes instantly. Companies like FedEx use these systems to reduce idle time, cut fuel consumption by up to 15%, and ensure faster customer deliveries.

What role do predictive analytics play in fleet maintenance?

Machine learning models process historical and real-time sensor data to predict vehicle wear. For example, UPS leverages this technology to schedule proactive maintenance, minimizing breakdowns and extending fleet lifespan while keeping routes operational.

Can AI adapt routes during unexpected disruptions?

Yes. Multi-agent systems evaluate variables like road closures or last-minute orders, recalculating paths within seconds. Amazon’s delivery network uses this approach to maintain 99% on-time rates even during peak demand or accidents.

How do IoT devices enhance logistics operations?

Sensors in vehicles transmit location, speed, and engine health data to centralized platforms. Coupled with AI, this enables granular tracking—DHL, for instance, reduced empty miles by 12% using IoT-driven insights to optimize load balancing.

What challenges arise when integrating AI into existing fleets?

Legacy systems often lack compatibility with modern AI tools. Transitioning requires upfront investments in cloud infrastructure and staff training. However, firms like Walmart achieved ROI within 18 months through reduced fuel costs and improved driver productivity.

Will autonomous vehicles impact AI routing strategies?

Autonomous trucks from companies like Tesla and Waymo rely heavily on AI for route planning. These vehicles optimize speed, charging stops, and traffic navigation autonomously, potentially cutting long-haul logistics costs by 30% in the next decade.