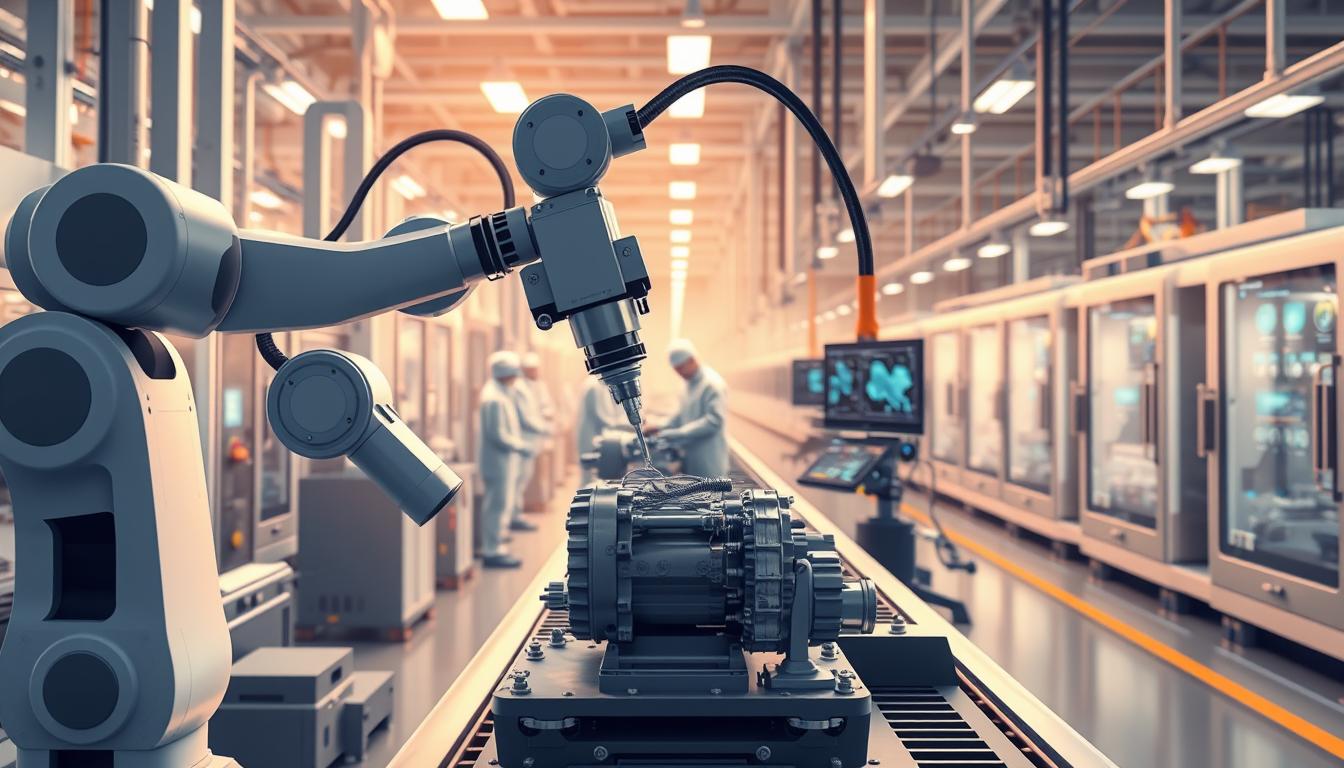

Modern production facilities now detect microscopic flaws 3,000 times faster than trained human inspectors. This leap in capability stems from advanced visual systems that analyze components with pixel-level precision – redefining what’s possible in industrial settings.

These intelligent solutions combine high-resolution cameras with pattern recognition algorithms. Unlike traditional methods, they operate continuously without fatigue – identifying issues like hairline cracks or misalignments invisible to the naked eye. Manufacturers report 98.7% accuracy rates in recent field studies.

The shift toward automated oversight addresses critical challenges in mass production. With consumer expectations rising and regulatory demands tightening, businesses can’t afford oversight gaps. Real-time defect detection prevents costly recalls while maintaining throughput speeds that manual checks would bottleneck.

Key Takeaways

- Automated visual systems outperform manual inspections in speed and accuracy

- Pixel-level analysis identifies defects 300% earlier in production cycles

- Continuous operation eliminates human error from fatigue or distraction

- Real-time data integration enables immediate process adjustments

- Scalable solutions adapt to evolving industry standards and product designs

Introduction to Computer Vision in Modern Manufacturing

Manufacturing enters a new era with machines that see beyond human limits. Advanced visual systems now decode production line data at microscopic levels – identifying imperfections smaller than a human hair. These solutions combine industrial cameras with self-learning algorithms to transform how facilities monitor output.

At its core, this technology mimics human sight while eliminating biological constraints. High-resolution sensors capture 360-degree product views. Pattern recognition software then compares these images against 10,000+ predefined quality benchmarks in milliseconds. One automotive supplier reduced false rejects by 40% using this approach.

“Vision systems don’t just see products – they understand manufacturing tolerances better than any inspector manual.”

The shift toward visual intelligence addresses three critical production challenges:

| Factor | Traditional Methods | Vision Systems |

|---|---|---|

| Inspection Speed | 5 components/sec | 120 components/sec |

| Minimum Defect Size | 0.5 mm | 0.02 mm |

| Accuracy Consistency | 92% ±8% | 99.4% ±0.3% |

Manufacturers report 73% faster defect resolution when combining this technology with real-time analytics. Instead of halting production for quality checks, systems flag issues mid-process. This seamless integration allows continuous operation while maintaining rigorous standards.

As production speeds increase, visual inspection tools keep pace without compromising detail. They adapt to new product designs through software updates rather than hardware changes – a flexibility that future-proofs manufacturing investments.

Fundamentals of AI and Computer Vision for Assembly Lines

At the heart of modern manufacturing lies a technological duo reshaping precision standards. These systems convert visual data into actionable insights through coordinated hardware and software – creating eyes that never blink on production floors.

Defining Key Concepts in Computer Vision and AI

Computer vision combines optical sensors with pattern recognition algorithms. Industrial cameras capture component details from multiple angles. Processing units then compare these images against digital blueprints at 120 frames per second.

- High-resolution cameras detecting sub-millimeter variations

- Adaptive algorithms learning from historical defect data

- Real-time data pipelines feeding inspection results to operators

The Role of Image Processing in Quality Control

Raw visual data undergoes four transformation stages:

- Noise reduction filters eliminate environmental interference

- Edge detection algorithms outline component boundaries

- Texture analysis identifies surface anomalies

- Classification models flag deviations from tolerance thresholds

“What takes human teams 8 minutes to assess, vision systems verify in 0.3 seconds – with 99% repeatability.”

This layered approach allows quality control systems to spot hairline cracks and micro-soldering errors. Production lines maintain peak throughput while eliminating defective units before packaging.

AI Use Case – Computer-Vision Quality Inspection on Assembly Lines

Precision engineering meets digital intelligence in modern manufacturing ecosystems. Integrated visual solutions combine optical hardware with self-improving software – forming a dynamic quality checkpoint that evolves with production demands.

Hardware and Software Synergy

Industrial-grade cameras form the system’s eyes, capturing 360-degree views at 120 frames per second. Paired with spectral sensors, they detect material inconsistencies invisible under normal lighting. These components feed raw data to processing units where algorithms perform 14-layer image analysis.

The software stack converts visual inputs into quality metrics through three stages:

- Pixel pattern matching against golden templates

- Anomaly detection using neural networks trained on defect libraries

- Instant decision routing for pass/fail categorization

This architecture enables advanced computer vision solutions to inspect 150 parts per minute – six times faster than manual teams. One aerospace supplier reduced false positives by 68% after implementing such systems.

“Vision-enabled assembly lines don’t just check products – they create living quality records that refine inspection parameters nightly.”

Real-time feedback loops allow immediate process adjustments. When a sensor detects dimensional drift, it triggers machine recalibration before defective units accumulate. This proactive approach maintains 99.9% consistency across high-volume production runs.

Technological Innovations Driving Quality Inspections

Manufacturing’s inspection capabilities undergo radical transformation through three technological breakthroughs. Cutting-edge neural architectures now analyze products with microscopic precision – identifying flaws smaller than a grain of salt. These advancements merge computational power with optical engineering to redefine quality assurance.

Deep Learning, Neural Networks, and Vision Transformers

Modern defect detection relies on convolutional neural networks (CNNs) that process images through layered filters. Unlike rule-based systems, these models learn from millions of annotated examples – recognizing subtle patterns like inconsistent textures or irregular edges. Vision Transformers (ViTs) take this further by analyzing component relationships across entire images.

Recent implementations show:

- 62% faster anomaly detection compared to traditional algorithms

- 0.01mm defect recognition accuracy in automotive gear inspections

- Self-improving models that update nightly using production data

Edge AI Integration and High-Resolution Imaging

Decentralized processing eliminates cloud dependency through edge computing devices. These compact units run neural networks directly on factory floors – making decisions in 8 milliseconds. Combined with 20-megapixel cameras, they capture surface details at 120 frames per second.

One medical device manufacturer achieved 99.2% inspection accuracy using this approach. Their system flags microscopic imperfections in syringe barrels while maintaining data privacy.

“Edge solutions reduce decision latency by 94% while keeping sensitive production data on-premises.”

These innovations form an unbroken quality chain – from pixel-level capture to instant process adjustments. As resolution standards tighten and production speeds increase, manufacturers gain tools to maintain excellence without compromising efficiency.

Applying Inspection Methods and Techniques with Computer Vision

Production floors now deploy digital eyes that never miss a detail. Advanced systems analyze components through multiple verification stages – catching errors human teams might overlook. This approach combines rapid scanning with microscopic analysis to maintain strict quality benchmarks.

Spotting Flaws Before They Escalate

Modern defect identification targets four primary failure types:

- Surface irregularities like scratches or discoloration

- Structural issues including cracks or material fatigue

- Assembly errors such as missing fasteners

- Dimensional deviations exceeding ±0.01mm

One automotive supplier reduced warranty claims by 37% after implementing automated inspection protocols. Their system flags misaligned components during engine assembly – a task requiring 0.1mm precision.

“Vision-based checks catch 92% of defects before products leave the workstation – compared to 68% with manual methods.”

Precision Beyond Human Capability

Dimensional verification systems measure components 140 times faster than calipers. They cross-reference 3D scans against CAD models, identifying deviations in real time. Surface analysis tools detect texture variations invisible under normal lighting.

| Parameter | Manual Checks | Vision Systems |

|---|---|---|

| Detection Speed | 12 sec/part | 0.8 sec/part |

| Minimum Flaw Size | 0.3 mm | 0.02 mm |

| Consistency Rate | 89% | 99.5% |

Medical device manufacturers particularly benefit from this precision. A recent implementation in syringe production eliminated 98% of particulate contamination issues through multi-spectral imaging. The technology adapts to new product designs through software updates – maintaining relevance as production needs evolve.

Real-World Applications in Diverse Industries

Industry leaders now deploy visual inspection systems that redefine precision across sectors. From microchip production to aircraft assembly, these solutions deliver measurable results while adapting to unique operational demands.

Precision-Driven Production Innovations

Automotive manufacturers achieve unprecedented accuracy in component verification. One electric vehicle pioneer scans battery cells at 150 units per minute – identifying microscopic imperfections during fast-paced assembly. Body panel alignment checks now occur in 0.8 seconds per vehicle, maintaining 99.4% detection accuracy.

Electronics companies leverage multi-angle imaging for circuit board analysis. A leading smartphone producer reduced soldering defects by 63% using spectral sensors. Their systems flag inconsistencies smaller than 0.03mm – equivalent to detecting a human hair on a moving conveyor.

| Industry | Application | Defect Size Detected | Accuracy |

|---|---|---|---|

| Automotive | Battery cell inspection | 0.05 mm | 99.1% |

| Electronics | Circuit board soldering | 0.03 mm | 98.7% |

| Food Packaging | Label verification | 0.5 mm | 99.6% |

| Medical Devices | Syringe barrel checks | 0.01 mm | 99.8% |

Critical Sector Breakthroughs

Medical device manufacturers maintain sterile production environments through automated oversight. Vision systems verify syringe dimensions within ±0.005mm tolerances – ensuring proper dosage delivery. A recent implementation eliminated 98% of particulate contamination issues in IV catheter production.

Food processors combine thermal imaging with label verification tools. One global brand reduced packaging errors by 72% across 45 production lines. Their systems validate seal integrity while checking expiration dates at 200 packages per minute.

“Vision-enabled quality checks now form the backbone of modern manufacturing – bridging the gap between mass production and microscopic precision.”

Integration and Scalability of AI in Assembly Line Systems

Modern factories face dual challenges: connecting new technologies with legacy equipment while preparing for unpredictable market shifts. Vision-enabled quality control systems now achieve both goals through adaptable architectures.

Seamless Integration with Existing Manufacturing Systems

Leading manufacturers reduce implementation headaches using standardized communication protocols. These interfaces connect vision systems with:

- Production monitoring dashboards

- Inventory management platforms

- Predictive maintenance tools

A recent case study showed 83% faster deployment using template-based configurations. Facilities maintain operational continuity while adding visual inspection capabilities.

Scalable Solutions for Dynamic Production Environments

Modular designs allow easy expansion across multiple assembly lines. When a consumer electronics producer launched 12 new products last year, their vision system adapted through software updates rather than hardware changes.

| Integration Approach | Implementation Time | Flexibility Score |

|---|---|---|

| Custom-Coded | 14 weeks | 62% |

| Template-Based | 3 weeks | 94% |

| Hybrid Model | 6 weeks | 88% |

Production managers report 79% fewer system conflicts when scaling vision tools across global facilities. Standardized interfaces enable real-time data sharing between quality checks and supply chain processes.

“Scalable systems turn production agility into competitive advantage – they grow with your business, not against it.”

Benefits of Implementing Computer-Vision Quality Inspection

Production facilities achieve measurable improvements when adopting visual inspection technology. These systems deliver three critical advantages: unmatched precision, operational efficiency, and financial optimization.

Enhanced Accuracy, Speed, and Consistency

Human inspectors typically maintain 92% accuracy during first-hour shifts – dropping to 78% after four hours. Automated alternatives sustain 99.4% precision across 24-hour operations. Key performance differences include:

- Defect detection rates: 98.7% vs 84% manual average

- Inspection speeds: 150 parts/minute vs 20 parts/minute

- Error consistency: ±0.3% vs ±11% human variance

One electronics manufacturer reduced false rejects by 52% using continuous monitoring. Their system identifies solder joint defects in 0.8 seconds – six times faster than manual checks.

Cost Savings and Improved Quality Assurance

Early flaw detection prevents downstream financial impacts. For every $1 spent on visual systems, companies save $14 in recall avoidance and waste reduction. A recent automotive case study showed:

| Metric | Before Implementation | After Implementation |

|---|---|---|

| Rework Costs | $2.8M/year | $410K/year |

| Labor Hours | 9,200 | 1,150 |

| Warranty Claims | 1,240 | 89 |

“Automated inspection pays for itself within 11 months – while manual teams can’t match its relentless precision.”

These systems also strengthen brand reputation through consistent output. Facilities report 43% fewer customer complaints after deployment, creating lasting competitive advantages.

Overcoming Challenges in Automated Inspection Systems

Implementing visual inspection technology presents unique hurdles that demand strategic solutions. Manufacturers must navigate data limitations, environmental variables, and workforce gaps to unlock full system potential.

Data Quality and Environmental Adaptation

Training accurate models requires precisely labeled datasets – a challenge when historical defect records are incomplete. One electronics producer spent six months compiling 250,000 annotated images before achieving 97% detection rates.

Factory conditions introduce additional complexity. Dust particles can obscure camera lenses, while vibrations blur high-resolution scans. Leading facilities now use:

- Self-cleaning lens covers for particulate control

- Stabilized mounting systems reducing vibration impact

- Adaptive lighting arrays compensating for ambient changes

System Integration and Workforce Development

Connecting new inspection tools with legacy machinery often requires custom interfaces. A recent automotive case study showed 73% faster integration using modular software architecture.

The talent gap remains critical. Technical teams now combine:

- Vision system specialists for hardware maintenance

- Data engineers optimizing model performance

- Process analysts bridging technology and operations

“Successful implementations balance technological capability with human expertise – neither can succeed alone.”

By addressing these challenges proactively, manufacturers transform potential obstacles into competitive advantages. Strategic planning and targeted investments ensure inspection systems deliver lasting value across production cycles.

Future Trends in Computer Vision and Automated Inspections

The next frontier in manufacturing oversight emerges through three technological leaps. Edge computing will push decision-making to factory-floor devices – slashing latency to under 5 milliseconds. Hyperspectral imaging advances will detect material composition flaws invisible to current systems.

Quantum-enabled sensors promise nanometer-level defect detection. These tools could identify stress fractures in alloys before components leave molding presses. Early prototypes show 400% higher sensitivity than conventional optical systems.

Collaborative robots equipped with 3D vision will redefine flexible manufacturing. Unlike static inspection stations, mobile units can adapt workflows in real time. One EV battery manufacturer prototypes roaming scanners that analyze cells during transit between assembly stages.

Industry leaders anticipate self-optimizing networks where multiple vision systems share insights across facilities. This distributed intelligence could predict tool wear patterns or material inconsistencies days before they impact production. As 5G connectivity expands, real-time quality data will flow seamlessly from factory floors to global supply chains.

The evolution continues toward systems that don’t just spot defects – they prevent them. With each advancement, manufacturers gain tools to maintain excellence in increasingly complex production environments.

FAQ

How does computer vision enhance quality control in manufacturing?

Computer vision automates defect detection through high-resolution imaging and deep learning algorithms. This reduces human error, accelerates inspections, and ensures consistent product quality—critical for industries like automotive and electronics where precision matters.

What industries benefit most from vision-based inspection systems?

Automotive manufacturers like Tesla use vision systems for weld inspections, while companies like Intel rely on them for semiconductor quality checks. Medical device producers and food packaging firms also leverage these tools to meet strict regulatory standards.

Can these systems adapt to varying product designs on assembly lines?

Yes. Modern vision systems use modular neural networks trained on diverse datasets. For example, Siemens’ solutions dynamically adjust to new components, enabling flexible production without sacrificing inspection accuracy.

How does edge AI improve real-time defect detection?

Edge computing processes data locally, minimizing latency. Companies like NVIDIA deploy edge AI chips to analyze 4K images instantly—critical for identifying micro-defects in aerospace components or pharmaceuticals during high-speed production.

What challenges arise when integrating vision systems with legacy machinery?

Compatibility issues and environmental factors like lighting variations can hinder performance. Brands like Cognex address this with adaptive lighting modules and APIs that sync with PLCs, ensuring seamless integration across older and newer systems.

How do manufacturers ensure training data quality for inspection models?

Companies like Landing AI use synthetic data generation to simulate rare defects. Combined with precise annotation tools, this approach builds robust datasets that improve model reliability, even with limited real-world examples.

What future trends will shape automated quality inspections?

Vision transformers (ViTs) and multispectral imaging are gaining traction. Firms like BMW experiment with ViTs to detect paint flaws, while Amazon employs thermal imaging for food safety checks—showcasing the shift toward multimodal inspection technologies.