Everyone who shops online has felt that small, nagging doubt: will this fit right? This introduction speaks to that moment and to teams trying to solve it for millions of shoppers.

The concept is simple and the stakes are high. Leading brands such as Amazon, Alibaba, Kering, and Nike invest in virtual fitting room systems to close the gap between browsing and in-store try-ons. These tools aim to lift conversion rates and cut returns by giving shoppers a believable preview of product fit and style.

At the core are three technical pillars: computer vision, augmented reality, and artificial intelligence working together to overlay garments on live video or avatars. That blend creates an interactive layer that boosts purchase confidence and yields actionable data on size, fit, and product interactions.

This is a product-led capability — not a gimmick. It operates across mobile, web, and in-store touchpoints and guides merchandising, sizing, and inventory decisions. Teams evaluating strategy can follow pragmatic paths: ready-made platforms or custom builds, chosen based on goals, differentiation, and data governance. Learn more in a technical overview here: virtual fitting room development.

Key Takeaways

- Virtual fitting rooms bridge online browsing and in-store try-ons to reduce returns.

- Three pillars—computer vision, augmented reality, and artificial intelligence—enable believable overlays.

- Major brands use this approach to improve conversion and capture fit data for merchandising.

- Deployments run across mobile, web, and in-store for a consistent customer experience.

- Teams should weigh ready-made vs. custom paths against goals and data control needs.

Why Virtual Fitting Rooms Matter Now: Market momentum and shopper behavior in the United States

Retailers face a clear inflection point: shoppers expect try-on certainty online. That expectation translates into measurable business outcomes—fewer returns, higher conversions, and stronger loyalty for early adopters.

Key stats: return rates, conversion lift, and market growth

Key stats: return rates, conversion lift, and market growth

Online returns hover near 30%, versus about 9% in-store; poor fit causes roughly 71% of those returns. When integrated thoughtfully, virtual fitting rooms can cut return rates by up to 30% and boost conversions as much as 200%.

| Metric | Baseline | Impact with virtual fitting |

|---|---|---|

| Online return rate | ~30% | Down up to 30% relative |

| Conversion uplift | — | Up to 200% |

| Market size (US/global) | $5.71B (2024) | Projected $24.30B by 2032 (19.8% CAGR) |

Consumer expectations for AR-powered, personalized retail experiences

Sixty-one percent of shoppers prefer retailers that offer augmented reality options, and 71% buy more often where these experiences exist. Customers expect interactive, personalized previews that remove doubt before checkout.

Why this matters for brands: better try-on clarity lowers cart abandonment and increases time on site. The same interaction data improves recommendations and inventory planning, creating a virtuous cycle that drives repeat business.

U.S. retailers should benchmark competitors and run rapid pilots to validate lift before scaling across catalogs. For market context and deeper forecasts, review this industry report: virtual fitting room market analysis.

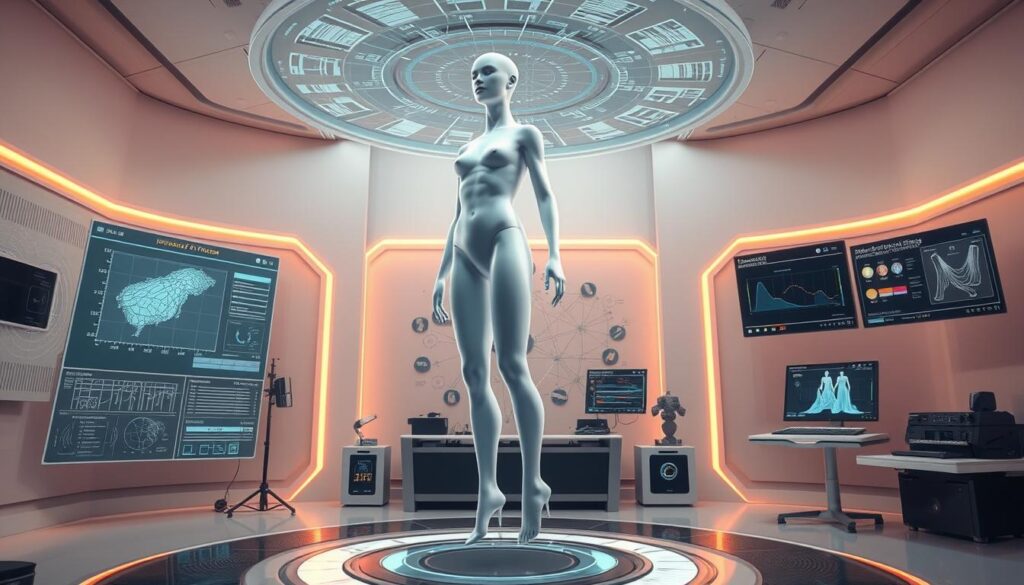

What a Virtual Fitting Room Is and How It Works

A modern fitting experience stitches together cameras, computer vision, and predictive models to show how clothes behave on a real body.

Core components that power a believable try-on

Computer vision interprets the scene and locates key landmarks. Augmented reality renders garments and tracks movement. Artificial intelligence refines recognition, lighting correction, and occlusion handling.

Inputs range from manual measurements to scans captured by smartphone cameras or depth sensors. Systems either create a 3D avatar or overlay a garment onto a live feed to show how a product will fit and drape.

From input to on-screen fit: the core pipeline

- Capture: collect measurements, posture, and images.

- Build: translate data into a body representation or avatar model.

- Render: apply garment geometry and textures through AR rendering.

- Simulate: use fabric metadata—elasticity, weave, and size charts—to show realistic movement.

Avatar-based try-on offers repeatable size control for complex garments, while live overlay wins on immediacy and simple UX. Teams should prototype both to match product assortments and customer segments.

| Component | Purpose | Device pathway |

|---|---|---|

| Capture | Gather body landmarks and measurements | Smartphone cameras; LiDAR for higher fidelity |

| Modeling | Convert measures into 3D models and segmentation masks | On-device or cloud processing depending on privacy needs |

| Rendering & Simulation | Render garments; simulate fabric behavior for credible fit | Optimized physics for real-time performance |

Privacy-by-design matters: transparent permissions and on-device processing build trust. Predictive models improve body part recognition, lighting robustness, and artifact reduction—raising confidence in fit while balancing speed and realism.

User Intent and Business Outcomes: Reduce return rates, increase conversions, and build loyalty

Shoppers seek clear signals about fit before they commit to a purchase. Meeting that intent turns uncertainty into action: clearer previews raise conversion and improve retention.

Direct impact on returns and margins: Better fit accuracy compresses return rates—deployments report reductions up to 30% and conversion uplifts up to 200%. Fewer returns lower logistics costs and protect contribution margins for brands.

Try-on interactions create valuable data on size selection, rejection reasons, and style affinities. Teams can feed that insight into personalization engines and smarter inventory planning to reduce stockouts and markdowns.

Beyond metrics, the experience builds trust. Customers remember seamless buys and return to brands that consistently get sizing right. Inclusive solutions that support diverse body types increase reach and equity.

- Measure conversion, return behavior, and engagement as leading indicators of success.

- Use interaction data to guide assortment, product iteration, and pricing decisions.

- Prioritize continuous UX improvements to remove friction in the try-on flow.

| Outcome | Business benefit | Metric |

|---|---|---|

| Improved fit | Fewer returns; higher margins | Return rates, contribution margin |

| Try-on data | Better personalization; smarter sourcing | Size selection, engagement |

| Inclusive experience | Broader customer loyalty | Repeat purchase rate, NPS |

Step-by-Step: How to Implement a Virtual Fitting Room Solution

Begin by tying product categories to clear KPIs. Align dresses, outerwear, or footwear to outcomes such as return reduction and conversion uplift. This focus keeps scope realistic and guides technical choices.

Discovery (Weeks 1–2): define input modes, avatar vs. live overlay, supported sizes, and target platforms. Validate user journeys and pick pilot SKUs that represent your catalog diversity.

Pilot, iterate, and scale: an agile launch loop

Plan a 16-week MVP sprint: stack selection (Weeks 3–5), capture and fit logic (Weeks 6–8), UI/UX (Weeks 7–10), eCommerce integration (Weeks 10–12), QA and pilot (Weeks 13–16).

Run a staged pilot with representative users. Test lighting, cluttered backgrounds, and low-end devices. Collect session data and map outcomes to carts and conversions.

- Build dual-mode capture: manual inputs plus camera-based scanning to maximize adoption.

- Integrate models that map body shapes to SKU sizing; plan continuous retraining.

- Design fast try-on entry points and simplify garment switching to reduce friction.

| Phase | Timeline | Typical cost drivers |

|---|---|---|

| Discovery & requirements | Weeks 1–2 | Workshops; product scoping |

| Tech stack & 3D pipeline | Weeks 3–5 | SDKs; asset tooling |

| Capture, fit logic, UI | Weeks 6–10 | 3D assets ($5k–$15k); fit engine ($3k–$7k) |

| Integration, QA, pilot | Weeks 10–16 | UI hours (100–140); integrations (60–100) |

Only scale when metrics hit thresholds for satisfaction and business impact. Document operational playbooks for asset updates and quality audits so brands sustain performance as catalogs grow.

For platform integration guidance, see Shopify’s guide to virtual fitting rooms. For a development case study and revenue perspective, review this project write-up.

Choosing the Right Technology Stack for Fitting Room Development

Decisions made now drive whether an initiative scales or stalls. Teams should pick components that match product mix, performance needs, and privacy rules.

AR SDKs, fit engines, and backend considerations

Compare SDKs for stability, tracking fidelity, and cross-platform support. Choose software that fits your roadmap and supports standard 3D models.

- Evaluate fit engines for measurement accuracy and brand-specific size deviations.

- Design backend infrastructure with GPU-enabled cloud nodes for heavy rendering and elastic autoscaling.

- Standardize meshes and textures to balance realism and performance; document upgrade paths.

Device capabilities and trade-offs

smartphone cameras scale best for broad reach; LiDAR adds depth where available. smart mirrors offer premium in-store experiences but cost more to deploy. Plan workarounds for frameworks that struggle with partial body tracking.

| Device | Strength | Trade-off |

|---|---|---|

| Smartphones | Scale, low cost | Varied camera quality |

| LiDAR-enabled phones | Better depth | Limited device pool |

| Smart mirrors | In-store UX | Higher hardware cost |

Final guidance: instrument observability, minimize PII retention, and choose extensible solutions so development remains efficient as catalogs and rooms grow.

Development Approaches: 3D models, diffusion pipelines, and pose/segmentation

Selecting the right approach starts by mapping product categories to technical strengths. Teams should match garment complexity to the method that delivers the needed realism and measurement control.

3D meshes for body and clothing

Create a user body mesh, align clothing meshes via landmarking, and run cloth physics for natural drape.

This path gives dynamic simulation and accurate size mapping, but asset creation and rigging add cost.

Diffusion and inpainting pipelines

Condition latent diffusion models on multi-angle garment datasets, masks, and labels to render apparel onto photos.

This accelerates visual output for many SKUs. Trade-offs include weaker control over exact fit and repeatable size metrics.

Pose estimation and body segmentation

Detect key points and build pixel masks to derive body measurements and guide fit logic.

Accuracy varies by body part; hybrid flows that combine automated measures with manual inputs improve results.

- Data prep: consistent lighting, clean backgrounds, and accurate labels improve model outcomes.

- Modular architecture: mix approaches by category—diffusion for tops, 3D for dresses, segmentation for shoes.

- Performance: optimize meshes, cache outputs, and offload heavy rendering to server GPUs.

Run pilots on representative product sets, track body measurements vs. returns, and iterate. Feedback loops refine models and guide scalable room development.

Product Data and 3D Asset Pipeline: From SKU metadata to photorealistic garments

Accurate product representation starts in the asset pipeline, not at checkout. A strong pipeline translates SKU records into reliable on-screen clothes that shoppers trust.

Digitizing garments means capturing geometry, high-fidelity texture maps, and fabric properties tied to size charts. Start by scanning or modeling accurate meshes and tagging material behavior — stretch, weight, drape, and reflectance. These fields feed physics-based rendering and fit simulations.

Standardized metadata improves recommendation quality and repeatability. Define fit category, brand sizing notes, and measurement tolerances so recommendation models map body profiles to a suggested size consistently.

Pipeline controls and governance

- Set quality gates: polygon budgets, texture resolution, and PBR consistency.

- Version assets so size or material updates propagate to the storefront.

- Create reusable templates and cloth libraries to speed catalog onboarding.

| Area | Purpose | Outcome |

|---|---|---|

| PLM/ERP sync | Align inventory and metadata | Accurate try-on availability |

| Automated checks | Validate dimensions vs. size charts | Fewer fit errors |

| Feedback loop | Return data to adjust fit mappings | Improved recommendations |

Plan for photogrammetry for complex garments and document asset guidelines for partners. This disciplined approach reduces rework and delivers consistent try-on results across catalogs and platforms.

Privacy, Compliance, and Data Ownership in Virtual Dressing Experiences

Handling sensitive body images and measurements requires clear policy, not assumptions.

Custom solutions offer stronger control over data and compliance than many ready-made apps. That control matters because images and measurements are highly sensitive.

Define what is captured—images, measurements, or behavior—and limit collection to what is essential for fit accuracy. Implement transparent consent flows and offer on-device processing or one-click deletion to reassure the customer.

“Privacy as a feature”

“Treat privacy as a competitive advantage that builds trust.”

Align retention and access policies to U.S. frameworks and document who can view sensitive assets. Keep first-party ownership so brands can govern marketing and personalization under clear rules.

- Encrypt imagery and metrics in transit and at rest; use role-based access.

- Vet SDKs and third-party vendors for compliance; require subprocessors to be contractually bound.

- Run privacy impact assessments when new capture modes or analytics are added.

| Area | Control | Outcome |

|---|---|---|

| Capture scope | Minimize fields | Lower risk |

| User controls | View/edit/delete | Higher trust |

| Vendor posture | Audits & contracts | Regulatory alignment |

Train teams on responsible handling to prevent scope creep. In practice, privacy and clear ownership turn room solutions into a trust signal that supports conversion and repeat business for users and customers alike.

Integrating a Virtual Fitting Room with eCommerce Platforms

Integrations decide whether a new fitting experience moves from novelty to measurable revenue. Choose an approach that aligns with platform strategy, data rules, and launch cadence.

Shopify, Magento, and headless sites accept SDKs and APIs that enable rapid deployment. SaaS SDKs speed time-to-market; custom modules give deeper control for brands that need it. Optimize camera prompts and permissions for smartphone cameras and add graceful fallbacks for older devices.

Practical integration checklist

- Map sessions to carts: tie try-on events to PDPs, cart actions, and checkout to measure assisted revenue.

- Sync catalog, size charts, and stock so recommendations match live availability.

- Build analytics pipelines to capture engagement, fit selections, and drop-offs.

- Link in-store smart mirrors and RFID triggers to digital profiles for omnichannel continuity.

- Secure media endpoints and add rate limits for peak traffic during promotions.

“Integrations must surface clear signals for product, marketing, and support teams.”

| Platform | Integration path | Key touchpoints |

|---|---|---|

| Shopify | SaaS SDK or app | PDP, cart, analytics |

| Magento | Custom module | Catalog sync, checkout events |

| Headless | API-first SDKs | Omnichannel profiles, in-store mirrors |

Document patterns and provide runbooks for support. Coordinate marketing to surface try-on entry points in PDPs and emails to maximize adoption of the room experience.

Performance, Accuracy, and UX: Overcoming fitting room technology challenges

Delivering a believable on-body overlay often comes down to balancing fidelity against real-time performance. Teams must manage rendering, tracking, and simulation trade-offs so the experience feels instant and reliable for shoppers.

Rendering and tracking constraints

Many augmented reality libraries favor inference speed over continuous tracking. That can produce lag or jitter when the phone moves fast or lighting changes.

Mitigation: optimize rendering pipelines, trim scene complexity, and compress textures to keep frame rates steady.

Improving body tracking and robustness

Partial body views break landmark models for hands and feet. Calibration screens that ask users to step back or rotate improve detection quickly.

Specialized detectors and fallback heuristics fill gaps when limbs are out of frame. Denoising, exposure adjustment, and occlusion handling keep overlays believable.

Real-time simulation and UX

Physics engines should be tuned with fabric datasets to simulate drape without killing performance. Cache intermediate computations to speed garment swaps and pose changes.

- Guide the user with framing prompts and progress indicators.

- Run A/B tests on fidelity versus speed to match your audience and device mix.

- Monitor FPS, tracking loss, and crash rates to prioritize fixes.

“Prioritize the user experience: small prompts and smart fallbacks often beat perfect visuals that run poorly.”

| Challenge | Action | Outcome |

|---|---|---|

| AR tracking limits | Calibration + adaptive thresholds | Fewer tracking losses |

| Partial body views | Specialized detectors + heuristics | More stable overlays |

| Simulation load | Physics tuning + caching | Smooth interactions |

Budgeting, Timelines, and Resourcing for Software Development

Planning money, time, and people up front makes product launches predictable and measurable.

Estimate cost centers clearly: 3D asset creation, fit engine training, UI/UX, integrations, QA, and ongoing ops. For a mid-size catalog, expect 3D asset work at roughly $5,000–$15,000 per SKU set and fit engine and model training near $3,000–$7,000. UI/UX typically runs 100–140 hours, while eCommerce integration requires 60–100 hours.

Anchor the project around a 16-week MVP roadmap from discovery to pilot. Set measurable KPIs—conversion uplift, return reduction, and satisfaction targets—before scaling. Allocate early time for data preparation and pipeline setup; poor inputs raise costs and delay launches.

Right-size resourcing: combine in-house product leadership with specialist partners for 3D, model training, and asset pipelines. Build contingency for iteration cycles after pilot feedback, especially for fit accuracy and UX tweaks.

Practical guidance

- Define ongoing costs: content updates, model retraining, infrastructure, and support to reveal full TCO.

- Phase category rollouts to accelerate time to value while building internal capability.

- Contract terms must protect IP and data rights to preserve long-term flexibility.

- Agree milestone gates across finance, merchandising, and engineering to avoid scope creep.

- Treat the first 90 days post-launch as dedicated optimization sprints to lock in ROI.

| Area | Typical cost or effort | Business impact |

|---|---|---|

| 3D asset creation | $5k–$15k per SKU set | High realism; faster conversions |

| Fit engine & training | $3k–$7k initial | Improved size accuracy; lower returns |

| UI/UX | 100–140 hours | Adoption and retention |

| Integrations & QA | 60–100 hours + testing | Reliable launch and analytics |

| Ongoing ops | Monthly retraining, infra | Sustained accuracy and uptime |

Build vs Buy: Custom virtual fitting room vs ready-made solution

A pragmatic buy-versus-build choice balances time-to-market against long-term control and data governance. Teams should evaluate trade-offs by outcome, not emotion.

Speed and launch: Off-the-shelf solutions deliver fast deployment and predictable features. They reduce initial development and offer vendor-managed updates.

Control and ownership: A custom virtual approach gives brands full governance over data, UX, and integration. Custom development lets teams tune accuracy, connect PLM/ERP, and avoid vendor lock-in.

Cost, scale, and strategic differentiation

Upfront costs are higher for bespoke builds, but recurring SaaS fees and limited flexibility can raise long-term total cost of ownership for packaged tools.

- Custom solutions scale to roadmap priorities and align infrastructure to growth.

- Proprietary fit logic and signature visuals create real brand differentiation.

- Vendor-managed platforms trade control for faster time to market and lower internal resourcing needs.

“Pilot with a packaged SDK, validate impact, then graduate to custom development where differentiation and data control matter most.”

| Criteria | Off-the-shelf | Custom build |

|---|---|---|

| Speed | High | Moderate |

| Data ownership | Limited | Full |

| Scalability | Constrained by vendor | Aligned to business |

| TCO over 5 years | Subscription heavy | Higher upfront, lower long run |

Use objective criteria—accuracy, UX, privacy, and roadmap fit—to guide the decision. Define exit strategies up front to limit lock-in and protect future innovation.

AI Use Case – Virtual Fitting Rooms with AR and AI: Measuring ROI and scaling success

Measuring impact begins with clear metrics tied to revenue and user behavior. Teams that track outcomes can prove value fast and prioritize what scales.

KPIs to monitor:

- Size accuracy — percent of orders where suggested size matched final purchase.

- Return rate reduction — programs report up to 30% fewer returns when fit improves.

- Conversion uplift — try-on interactions can lift conversions as much as 200% for some product sets.

- Customer lifetime value — cohort analysis shows repeat purchase gains as fit confidence grows.

Continuous improvement and predictive insights

Feed try-on events, purchases, and returns into model training so recommendations sharpen over time.

Use cohort analysis to measure how size accuracy affects repeat buys and CLV. Attribute revenue by mapping try-on sessions to carts and orders — measure assisted conversions, not only last-click.

| Metric | Action | Outcome | Cadence |

|---|---|---|---|

| Size accuracy | Set category thresholds; run A/B tests | Fewer mismatches; lower return rates | Monthly |

| Return rates | Map returns to try-on behavior; retrain models | Reduce return volume up to 30% | Quarterly |

| Inventory planning | Deploy predictive analytics by size/style | Lower stockouts; fewer overstocks | Seasonal |

| Technical health | Track latency, crash rate, tracking loss | Stable user experience; higher adoption | Weekly |

Governance and scale: Build executive dashboards that blend business KPIs and technical health. Establish a cadence for monthly retraining, quarterly UX reviews, and seasonal content audits. Share insights with design and merchandising so product choices reflect real-time fit and rejection signals.

Conclusion

The room is a capability, not just a checkbox. Treating virtual fitting as strategic yields measurable gains: higher conversion, fewer returns, and richer shopper signals that inform product and inventory choices.

Start pragmatic: run focused pilots tied to clear KPIs, validate impact on carts and returns, then scale with a disciplined asset pipeline and governance. Brands such as Gap and Adidas—alongside platforms like PICTOFiT—show how avatar and sensor-driven approaches can scale.

Design choices matter: avatar-based try-on and live overlays each suit different product sets and customers. Prioritize trust and privacy; transparent policies accelerate adoption and strengthen brand loyalty.

Define KPIs, pick an initial category, and align product, engineering, merchandising, and CX. That cross-functional ownership turns a dressing room pilot into a durable experience that helps customers buy the right clothes.

FAQ

What is a virtual dressing room and how does it work?

A virtual dressing room blends computer vision, augmented reality, and machine learning to let shoppers try on garments digitally. The system captures body measurements via smartphone camera, LiDAR, or smart mirrors, creates a body map or avatar, and overlays photorealistic clothing using 3D meshes or diffusion-based rendering. This process produces real-time garment simulation and fit recommendations that guide size selection and reduce returns.

Why do retailers invest in this technology now?

Shoppers expect personalized, interactive experiences; online return rates for apparel remain high and eat margins. Retailers that deploy high-quality try-on tools see conversion lift, lower returns, and stronger customer loyalty. Market growth, faster device capabilities, and richer product data make adoption practical and impactful for eCommerce and omnichannel strategies.

What core components should a brand evaluate when choosing a solution?

Key components include an accurate fit engine, AR SDKs (for example Apple’s ARKit), body mapping and pose estimation, a robust backend for session data, and a 3D asset pipeline for garments. Consider device compatibility—smartphone cameras, LiDAR, and smart mirrors—and integration points with platforms like Shopify or Magento.

How does digitizing garments work and why is metadata important?

Digitizing garments involves creating geometry, textures, and fabric properties, then linking them to SKU metadata and size charts. Standardized metadata improves size recommendations and recommendation accuracy, enabling consistent fit across categories and reducing post-purchase returns.

Can brands build in-house or should they buy a ready-made solution?

Build offers control and differentiation but requires investment in 3D assets, fit models, and integrations. Buy accelerates time-to-market and reduces upfront risk but may limit data control and customization. Assess total cost of ownership, vendor lock-in, and strategic goals before deciding.

What are typical KPIs for measuring success?

Track size accuracy, return rate reduction, conversion uplift, average order value, and customer lifetime value. Also monitor engagement metrics—session length, try-on rate—and operational metrics like asset production velocity and latency.

How should a retailer pilot and scale a solution?

Start with discovery to define product categories, KPIs, and user journeys. Run an agile pilot on a focused category, gather usage and fit feedback, iterate model and asset quality, then scale across SKUs and channels. Use continuous feedback loops and predictive insights to refine recommendations.

What device trade-offs impact accuracy and UX?

Smartphone cameras are accessible but vary in quality; LiDAR improves depth and body measurement accuracy; smart mirrors offer in-store convenience but add hardware cost. Choose devices based on target audience, desired fidelity, and budget.

How do developers handle pose estimation and body segmentation?

Teams use pose estimation and segmentation models to extract landmarks and silhouette, then fit 3D meshes or generate inpainted try-ons via diffusion pipelines. Accurate landmarking and robust segmentation across body shapes are critical for reliable size and fit guidance.

What performance challenges should teams anticipate?

Common constraints include rendering performance, tracking under varied lighting, and latency in real-time simulation. Optimizing rendering pipelines, model size, and using edge processing where possible improves responsiveness and user satisfaction.

How is user privacy handled and who owns the data?

Privacy best practices include on-device processing for measurements, explicit consent, data minimization, and clear ownership terms. Brands should define data retention, compliance with regulations, and whether session data feeds product analytics or stays private to the user.

How do integrations with eCommerce platforms work?

Integrations map try-on sessions to carts via SDKs and APIs, synchronize SKU and size metadata, and feed analytics into platforms like Shopify or Magento. Headless commerce setups often use API-first architectures to support real-time personalization and omnichannel workflows.

What does budgeting and resourcing typically include?

Budget items include 3D asset creation, fit engine licensing or development, UI/UX, device testing, and platform integrations. Plan for an MVP roadmap with staged milestones: discovery, prototyping, pilot, and scale, and allocate resources for ongoing model training and asset updates.

How can brands continuously improve fit accuracy?

Use feedback loops from returns and customer reviews, refine size charts, retrain fit models on real-world data, and enhance 3D assets. Predictive insights—such as sizing suggestions based on purchase history—help reduce returns and improve conversion.

Which technologies power photorealistic try-on and garment behavior?

Photorealism relies on high-quality textures, physically based rendering, cloth simulation in 3D meshes, and advanced diffusion or inpainting workflows for image-based try-on. Fabric physics and correct scaling produce believable drape and movement.